Nov 17, 2020

Hydraulic Boat Lifts – Updated

Hydraulic boat lifts have shown improvements in getting rid of the complexity of a standard cable lift. Today’s hydraulic lifts do not require a pendant to cycle. Push the button on your wireless remote, and the unit will do the rest. (like a garage door opener).

Hydraulic Boat Lift

Simplicity – New technology allows Hydraulic boat lifts to get rid of all the cables and pulley problems. There are no cables to jam or break. You can not wind or unwind too far in either direction. There is NO possibility of whiplash in the cables because there aren’t any.

The Hydraulic boat lift has a straightforward design. It does not rely on cables, pulleys, or screws to raise or lower your boat like other products.

Quiet Operation – Today’s Hydraulic technology operates without the old “rattle and clank” that many boat lift brands produce during operation.

The simple “hum” of a hydraulic pump in operation is quiet and more pleasing than the mechanical rattle of a winch gear at work.

Update – Using the latest technology, ShoreMaster now offers the Whisper Winch 2. This latest winch does not have any clanking sounds, and the cables wind smoothly and evenly.

Faster Speeds – Prior to hydraulic technology, boat lift owners only had two ways to power their lift:

- By hand or

- By attaching a motor to the lift winch

While the latter may have improved operational convenience, it didn’t improve the boat lift’s simplicity. Rarely would it produce speeds faster than a hydraulic boat lift provides. Hydraulic boat lifts are fast while remaining quiet and incredibly simple.

Hydraulic Boat Lift features

Lifting Heights – ShoreMaster – 48″ – 60″ lifting height

Sunstream – 48″ – 72″ lifting height

Lifting Capacities – Up to 32,000#

A Partial step

Some brands have come out with a Hydraulic boat lift that still utilizes cables & pulleys as a partial measure. While they solved one problem (quiet operation), they still use cables and pulleys.

The ShoreMaster hydraulic boat lift is simple, quiet, fast, and uses NO cables or pulleys.

These three words sum up everything that a hydraulic boat lift should be

Simple, quiet, and fast.

For more information and what works best for your area, contact Jerry @ (920) 493-4404 – TODAY – or – fill out this simple quote request form.

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay and 1 mile past the intersection of Cty MM (heading north). Look on the right at the intersection of Idlewild Road and Hwy 57.

ARE WE OPEN?

Pier & Waterfront Solutions remains “open.”

We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service you expect.

Please use face masks

Because the virus has increased its spread, PWS is conducting as much business as possible by email, text, or phone.

Site visits continue as usual. When in-person contacts are necessary, we follow “social distancing” guidelines as closely as possible.

Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number when you call.

We provide estimates and quotes by email to make the process paperless, faster, and safer. We hope everyone will stay safe with these measures, and we will be back to normal operations soon.

What can YOU do?

Please conduct as much business as possible via emails, messaging, and emails. When you see our crews on-site, please practice “social distancing.”

Call, message, or email us with any questions.

Thank you for allowing us to work with you safely.

Let’s all stay safe!

Oct 13, 2020

Steel or Aluminum Docks – Is Steel your best choice?

Aluminum ShoreMaster Dock

Pier & Waterfront Solutions has strongly recommended aluminum docks from ShoreMaster for years.

Today, the rising waters and intense storm activity has forced us to re-examine our customer needs.

What was the result?

If you’re in a protected or semi-protected area, we still recommend aluminum docks from ShoreMaster. These are the strongest aluminum docks on the market. When combined with their Flow-Thru decking, you have a winning combination for most needs.

But what if you aren’t in a protected area? Is steel a better choice?

Steel 3-Season Pier

The high waters have changed the environment in the last several years. For Lake Michigan and Green Bay customers, we saw a need to develop a new version of a dock. In March 2020, we announced the latest innovation from Pier & Waterfront Solutions – the steel 3-Seasons Pier.

When did this come about?

Initially developed in 2017 and 2018, the first docks were built and tested in 2019. In 2020, we put the 3-Season Pier in our sales area, where it quickly sold out.

Imagine having the most massive steel dock in the state to withstand the waves. Now, combine that with SunWalk decking, and you have another winning combination.

What else is different about the Steel 3-Season Pier?

It comes with 20-foot ramps – not the typical eight or 10-foot ramps you are accustomed to. Why is this important? A 20-foot ramp means you have a gentle rise up to the dock, and you don’t have to get a running head start to get there. It’s easier for young and old to access the pier.

Anything else?

Instead of having a mere 4′ x 8′ (32 square foot) “L” section to socialize on, you have a 4′ x 10′ (40 square foot) “L” section. The kids will no longer trip over your feet as they run around.

There’s 25% more room to sit or socialize on. The massive “L” section will also get you away from the boat lift area and the supplies you want to load.

What’s important when deciding what material to use?

When deciding on the type of material to use on your dock, it is essential to use strong materials that will last season after season.

Even the legs are massive. They measure 2-3/8″ outside diameter versus the next closest one 1-7/8″.

You can follow this link 3-Seasons Pier for the technical details of why it’s the strongest and best dock for you.

Aluminum Docks

Aluminum docks have always been popular due to their low maintenance and durability. Some people choose to install and remove their piers themselves, and the lighter weight helps.

Aluminum Dock Pros:

- Low Maintenance & Durability – Aluminum frames do not rust.

- Light-weight – Aluminum docks are easier to install.

Cons:

- More expensive – The biggest drawback for aluminum docks is that it can be more costly than it’s steel counterpart.

Steel Docks

Steel docks are popular because of their cost efficiencies and superior strength,

Pros:

- Strength: For heavily used piers, steel will be the best option for its strength, which will withstand constant use.

- Galvanized steel: At Pier & Waterfront Solutions, we use galvanized steel to prevent rusting.

Cons:

- Heavier weight: While the dock is known for its superior strength, the weight can also prevent buoyancy issues.

Ready to learn more?

At Pier & Waterfront Solutions, we provide a free site survey to determine the best material and design for your next dock.

Contact Jerry today to get started!

Call 920-493-4404 or email Jerry@wisconsinpws.com

Where are we located?

Pier & Waterfront Solutions (PWS) specializes in ShoreMaster aluminum docks and now the 3-Seasons

Pier by PWS. We are located in the center of Door County at 7325 St Hwy 57 south Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Sep 1, 2020

What’s new in boat lift winches? Updated

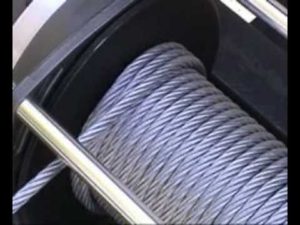

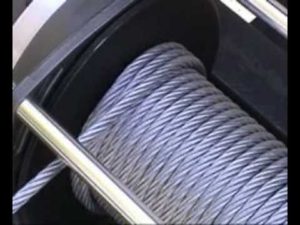

The Whisper winch from ShoreMaster was a significant improvement over other boat lift brand winches in 2018. ShoreMaster continues to be the leader in the Marine industry.

Most boaters were annoyed by the clanking noise generated when they turned the large wheel on their boat lift. That noise disappeared after the introduction of the Whisper winch in 2018.

Then, in 2019, they introduced another refinement – the Whisper Winch II.

This new winch gave you extended cable life by introducing a more substantial diameter drum. Why is this important? Having a 50% increase in winch diameter means there is less internal stress on the cable strands as they wrap around the drum.

The larger drum diameter, in turn, reduced internal chafing in the cable significantly. An added advantage is the galvanizing on the winch cable strands lasts longer.

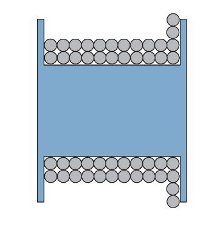

Typical Cable Stacking

What is cable stacking?

Today, there has been another improvement. The winch drum now has grooves cut into it to guide the cable smoothly around the drum. Cable “stacking” is virtually eliminated.

Without cable “stacking,” the life expectancy of the cable increases. It also means fewer cable “shocks” and abrasion. By “shocks,” we are not referring to an electrical shock.

When a cable begins to stack up along the edges of the drum, it will climb two or more levels. At that point, the cable will slip off the stack, and the boat falls about 1/4 to ½” in an instant. The “falling” results in a thunderous noise which “shocks” the person operating the winch. That doesn’t seem like much movement, but that 1/4″ – ½” can mean a broken cable if it is weak.

The “shock” is dangerous for the cable if the cable is in a weakened state. The cable is free to move, and then all the weight of the falling boat is suddenly applied.

Picture a moving car hitting an immovable object. The “shock” is similar to hitting an unmovable object with a moving one-ton object.

My boat lift cable broke…and I can’t get ….

One moment the boat is free to fall (albeit a short distance), and in the next moment, it snaps to a complete halt. All the pressure is on the cable at that point. Any weaknesses in the cable (rust, broken strands, frayed wires) could mean your boat will end up in the water and not necessarily floating.

With further testing, they realized that the main lifting cable could be changed back to stainless steel on the larger boat lifts. Now, ALL of the cables are stainless steel again.

BUT THAT’S NOT ALL!

There is still one more advantage to the Whisper winch II. In the past, two bolts mounted the winch to the leg post. The bolts meant that if you added a canopy later, the winch must be entirely removed.

Today, the winch clamps in a sleeve that fits snugly around the leg. There is a significant reduction of install time as a result. The clamp also ensures the winch is correctly installed. It can not be misaligned. Misalignment of the winch was easy to do with the winch bolted to the leg. These same bolts contributed to cable stacking also.

In Conclusion

The continued introduction fo these refinements keeps Shoremaster at the top of the best-in-class list.

Tell Your Friends & Family

Have friends or neighbors you believe should see this article? Email a link to this article – and Thank you!

You can visit Pier & Waterfront Solutions on Facebook also.

Don’t Forget – PWS is the expert when you have a waterfront problem!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, we are about 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look for the intersection of Idlewild Road and Hwy 57.

ARE WE OPEN?

Pier & Waterfront Solutions has remained “open.”

While all this is going on, we are working to maintain the trusted service you expect. That’s important to us.

We are conducting as much business as possible by email, text, or phone. Site visits will continue as usual. When in-person contacts are necessary, we follow “social distancing” guidelines as closely as possible.

Call, message, or use this simple request form to get answers and quotes.

Thank you for allowing us to work with you – safely.

Let’s all stay safe!

Aug 11, 2020

Stress – Even Boat Lifts experience it

Stress – Even boat lifts are under stress – this year more than ever before due to the high waters.

Why? High water increases the stress on your cables.

We’ve previously informed you of the danger to boat lift cables during a storm. If the waves hit the bottom of your boat it will momentarily lift the boat and then allow it to fall back on the rack. What if the cables are weakened by rust and frays? The “bouncing” effect can completely sever a cable into two pieces.

The boat only lifts a fraction of an inch – right?!!

How can that movement harm the cables?

Even though the boat only rises a fraction of an inch, the energy of the “falling” boat must be absorbed by the boat rack. The cables in each corner of the lift must, in turn, absorb the stress of a moving 3-5,000 pound boat.

Having said that, a weakened cable is in imminent danger of breaking. Think of an 80-100 lb jackhammer used to break up concrete. Even reinforced concrete can not withstand the movement of the bit hitting the concrete.

With a boat, you are talking about a potential 5,000 lb weight dropping on a rack compared to an 80-100 lb. weight.

Protect your cables! It only takes a minute or two to protect your cables from rust. It’s simple and easy to do. A convenient link* is provided below so you can learn more about this.

What are the defect warning signs?

There are warning signs of defects in your cables? If your cables look like any of these, it’s time to replace them. Need more information? Here’s an article that addresses this issue.

Always remember – it is possible to have broken strands inside your cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

What’s a quick way to reduce the stress on the cables?

At the beginning of the year, we place your boat lift in the requested location. We adjust the height of the legs based on what the current water level is.

Unfortunately, the water has continued to rise this year and that may no longer be suitable for the conditions you have today. Add to this the Seiche waves (pronounced “say-sh”) which are standing waves that form in a confined body of water. The friction of the wind against the surface of the water causes wave action.

As waves move towards the shoreline the water gets shallower and the moving waves rise higher. Standing waves, in general, can form in any type of semi-enclosed or enclosed body of water. When these rising waves hit the bottom of your boat the boat does what it is designed to do – it floats on the water.

Your Lift rack may be too close

The lift rack could be too close to the water to protect your boat with the rising water. As a result, you are not able to raise the boat high enough to keep it above the waves. On the other hand, If the rack is set too high in the water, you may not be able to get your boat on the lift. It’s a delicate balance. The variable is the changing depth of the water.

What can I do?

One way to raise the boat higher is to purchase longer legs and replace the standard lengths with new ones.

A less costly alternative is to simply move your lift closer to shore. It will be in shallower water and save you having to buy longer legs and the labor to install them.

If you keep the standard legs and don’t allow us to place the lift closer to the shore, you are inviting costly repairs or even replacements.

In Conclusion

Get out there and take care of those cables. Check out the link below. Then, consider moving the lift closer to shore.

* Wire Rope Lubrication link.

Tell Your Friends & Family

Have friends or neighbors you believe should see this article? Email them a link to this article – and Thank you!

You can visit Pier & Waterfront Solutions on Facebook also.

Don’t Forget – PWS is the expert when you have a waterfront problem!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, we are about 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look for the intersection of Idlewild Road and Hwy 57.

ARE WE OPEN?

Pier & Waterfront Solutions has remained “open.” We have implemented measures to ensure the safety of our employees and visitors. As of Aug 1st, Wisconsin mandates the use of face masks. We also endorse this to slow the spread of Covid-19. It’s the only known method to control the spread at this time.

While all this is going on, we are working to maintain the trusted service you expect. That’s important to us.

We are conducting as much business as possible by email, text, or phone. Site visits will continue as usual. When in-person contacts are necessary, we follow “social distancing” guidelines as closely as possible.

When can I see the display yard?

Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

How will I get my estimate?

We provide estimates and invoices by email to make the process paperless and faster. With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can YOU do to help our crews?

Please conduct as much business as possible via emails, messaging, and emails. When you see our crews working in your area, please practice “social distancing.”

Call, message, or use this simple request form to get answers and quotes.

Thank you for allowing us to work with you – safely.

Let’s all stay safe!

May 14, 2020

USED BOAT LIFT GUIDE – Part 2

Are you thinking about buying a used boat lift? This two-part series concludes with four additional items to check. Upon completion, we will have guided you through eight problems to look for when buying a used boat lift.

See Part 1 for the first four checks.

Here’s the second list of things to check:

- Does the cable wind smoothly and correctly on the winch?

- Do the cables have rust on them? Does it use galvanized or stainless steel cables?

- Are there any “kinks” or other visible problems on the cable?

- How often were they lubricated, and with what lubricant?

Does the cable wind smoothly around the winch?

Properly wound Boat lift cable

If you look up inside the winch housing, if it has an enclosure, you will be able to see how the cables are winding. It should be a smooth pattern without any “crossed” cables. If the winch has no outer covering, you can readily see the pattern.

The wire cable has a “memory” to it. Once the cable gets crossed, it will tend to do it again the next time the cable rewinds.

Typical Cable Stacking

If the cable is wrapping in layers, you will get a thunderous sound when the cable finally “falls off” the stack. This movement scrapes the galvanizing of the wire, and rust will form. The “shock” of dropping a 2,000# (or more) weight will also apply excessive stress on the cables.

Do the cables have rust on them?

Galvanized cables will rust over time. The movement of individual strands of the wire against each other cause rust. This movement occurs as they wrap around the winch and pulleys. There is no way to end this.

The only thing you can do is lubricate the cables. The lubrication reduces the friction between individual strands. Lubrication, in turn, lengthens the life of the cable. For more details click HERE.

Rust on the cable indicates that some galvanizing has worn off. Individual wire strands are compromised.

What about rust on a stainless steel cable?

Stainless steel does not rust, but it does pick up loose rust from the winch. Winches are plain steel with a painted surface. When the paint rubs off, the steel will rust and “bleed” onto the cable.

It’s much like a scratch on a car. The rust will run down the side of the vehicle.

The rust typically appears near the winch when the rack is in a lowered position. Under these circumstances, it’s ok. Try to lubricate the cables every year to slow this down.

Are there any visible signs of problems with the cables?

We recommend you lower the “rack” down, but DO NOT allow “slack” to form in the cables. Slack in the cables will allow the windings at the winch to unwind and cross over each other.

It’s much like a fishing reel getting snagged when there is no tension on the line.

Are the cables on the used boat lift adjusted equally?

If three of the four corner cables appear “tight,” the cables will need re-adjustment to re-distribute the weight equally.

Even proper positioning of the boat is essential.

If it takes excessive weight to lower the rack, look at the pulleys in each corner. Are they free to move? Is there sand, seaweed, or reeds packed around the pulleys? Remove any debris to free up the rack.

If any pulleys resist rotation, the rack will not lower smoothly. You must find out why the rack is not moving.

Note: In the case of jet ski lifts, the weight of the rack may not be enough to cause the rack to lower by itself. Have someone lean of the back of the lift to assist the rack in lowering. Still, hanging up? Check all the pulleys as above.

Check the fittings on the ends of the cable. Has rust formed on the fittings, or are there broken strands?

Caution– watch out for the ends of the cables. It’s a painful reminder of exposed strands.

Examine the entire length of the cable for frays (broken strands).

Caution – DO NOT run your hand up and down the cable without leather gloves. Broken strands on the cable will cause painful cuts on an unprotected hand. Ordinary cloth gloves will not protect your hand.

Are there any “kinks” or other visible problems?

Here are the warning signs of defects in your cables.

Frayed Boat Lift Cable

Broken cable strands

Cable damage

wire rope damage

If your cable looks like any of these, it’s time to replace them.

Warning – it is possible to have broken strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

Read this article to learn how to lubricate cables. Lubrication slows down premature corrosion. It’s simple and easy to do.

What is the proper lift cable maintenance?

Cable replacement requires a visual inspection of the lift cables. It’s best to inspect it while it is on dry land to check the critical points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Examine the vertical length of the cable for frayed wires, especially near the winch. Excessive fraying or corrosion near the winch is a top signal of damage.

CAUTION – Always wear leather gloves when sliding your hands along the cable. A frayed wire can cause painful damage to unprotected hands.

There are two types of cable wear:

- Internal cable abrasion- Occurs whenever strands work against each other under load.

- External abrasion – Occurs when the cable bends around the winch drum or against the side of the drum.

Every time the boat is raised or lowered, there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When the strands break, they lose strength.

Assuming the cable is well cared for, how long should it last?

Experts say that to be safe- replace a galvanized cable every two years. All things being equal, the stainless cable will last longer. Up to 2X as long.

A point often overlooked – internal abrasion and rust are hidden, and there may be no visible damage. A boat lift cable like this will fail without prior warning.

When in doubt, plan on replacing the cables. Trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

PWS handles Shoremaster cables and can provide new cables for all brands.

Nothing lasts forever – even boat lift cables.

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

John @ (920) 493-4405 or John@wisconsinpws.com – Scheduling & Service work