Aug 20, 2019

Cable Maintenance

In last weeks article, (https://wisconsinpws.com/boat-lift-cable/) we discussed why your boat lift cable would not last forever.

This week we get into more detail and explain what you can do. We discuss the most critical causes of cable problems and what you can do to protect them.

There are two types of cable material used for boat lifts:

- Galvanized; and

- Stainless steel.

Rust on galvanized cable

Galvanized Steel is made of carbon steel which on its own is not resistant to rust. It is made corrosion resistant by running the cable through a hot bath of molten zinc. As long as the coating is on the wire “fibers,” it will resist the formation of rust.

Stainless Steel is also made of carbon steel. However, when mixed with about 10% chromium, it will form a stainless steel cable. It resists oxidation or corrosion. The chromium in the steel forms a layer of chromium oxide that promotes resistance to corrosion.

When the stainless steel wire is exposed to oxygen, the protective coating will REGENERATE. The anti-corrosion protection of the chromium maintains the resistance of the steel to rust.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is durable, and each cable is sized to handle the loads created by your boat lift.

No – you can NOT increase the boat lift rating by merely increasing the size of the cable used. If you simply increase the diameter of the cable, you must also increase the size of the drum, or you risk early failure. The larger wire is stiffer and cannot bend around a smaller drum without damage.

Keep this information in mind if a neighbor or visitor wants to put their boat on your lift when it is empty. Know the weight of the new boat.

See https://wisconsinpws.com/boat-lift-calculations-part-4/ for additional information about cable maintenance.

Boat Positioning

Boat stern overhanging too far

Make sure your boat is positioned correctly on the lift. If it’s not far enough forward, it will put excessive weight on the rear cables and the frame structure. On the other hand, if the boat is too far forward, you may damage the lower motor assembly or break the front cables due to excess weight.

In general, a boat has most of its weight at the stern where the motor is. As a result, to maintain proper balance on your lift, the boat stern should be about 6″ to12″ from the lift rack. See the above article for more information.

When properly balanced, the weight is evenly distributed across the lift rack. A balanced boat prevents overloading one end of the lift.

Note – unusually long boats, may be an exception to the 6-12″ rule. You must be especially careful to find the proper balance. Proper balance will minimize potential damage to the cables.

To summarize, take care of your cables, and they will last for years.

What Cable Maintenance Can I do by myself?

1. Make a visual inspection of the cables regularly. It is helpful to do this when the lift rack is in its lowest position to expose more cable. Look for chafing, corrosion or a flat cable especially near the winch box.

Don’t forget – do this inspection with leather gloves on to protect your hands.

Boat Lift Cable Lubricant

2. At the beginning of the boating season, be sure to apply a burst of penetrating oil to the top of the cables around the winch drum. The penetrating oil will work its way down the wires as needed. Raise the rack halfway up and carefully apply another burst of penetrating oil to the winch drum. NEVER use grease on the cables. It traps moisture inside the strands. Do not be afraid to do it more often during the summer months, if you use the boatlift frequently.

Most quality lifts use Stainless Steel cables for a majority of cables and (1) galvanized cable as the main winch cable.

3. Watch the winch drum to ensure that the cable is wrapping smoothly on the drum.

Stainless steel lift cables also benefit from penetrating oil. We recommend this procedure in Spring, halfway through the boating season and again in Fall after removal.

To summarize, take care of your cables, and they may last for years. Remember, the cables and the winch do all the “work” on your lift. They do the lifting by raising the rack assembly with the weight of the watercraft on it. That’s a lot of weight so the cables must be well maintained.

In Conclusion

In Spring and Fall (and at least once during the summer months), put a short blast or two of PENETRATING oil on the cables wrapped around the winch drum from the top of the winch. Do not soak the wire until it drips when in the water. You don’t want to contaminate the water. Use only penetrating oil as the lubricant.

NEVER use grease (it traps the moisture inside the cable accelerating its deterioration).

Cable maintenance begins with inspecting cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed, if corrosion is present.

Check the alignment of all cables on the pulleys. Simply follow the cables down until they wrap around a pulley. Are they On a pulley or is the cable off to one side? Call PWS if they are.

With your watercraft on the rack – check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

Look for cable corrosion near the winch with the rack fully down (but without slack in the lifting cables.

Remember, the cables and the winch do all the “work” on your lift. They do the lifting by raising the rack assembly with the weight of the watercraft on it. That’s a lot of weight so the cables must be well maintained.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts, and accessories.

We are located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection with Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 13, 2019

NOTHING LASTS FOREVER – EVEN A LIFT CABLE

Typical Lift cable

That’s true! Your cables will eventually need replacement. When? That depends on you. If you’ve been around boat lifts for any length of time you have seen problems with boat lifts. Typical problems include corrosion, chafe, broken strands or kinks on the cables..

Let’s start by looking at the typical construction of a lift cable.

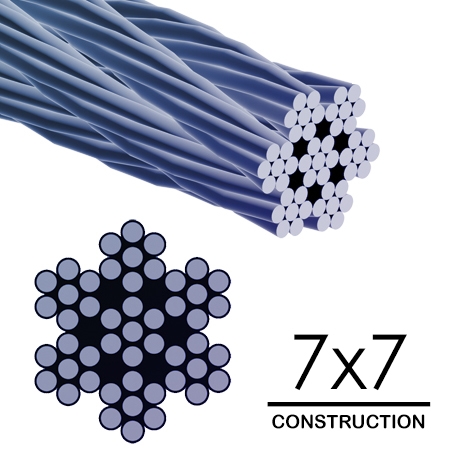

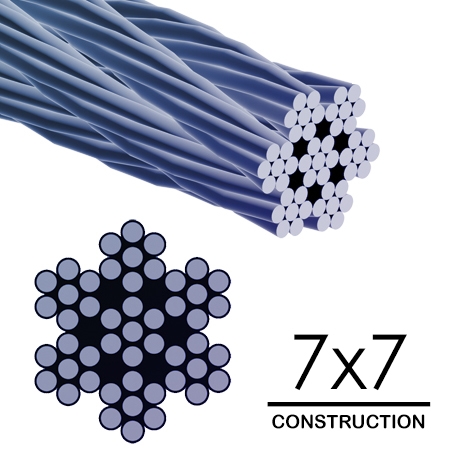

7 x 7 cable construction

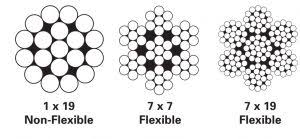

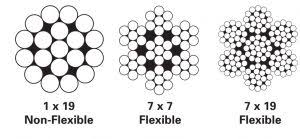

The most common types are the 7 x 7 and 7 x 19 construction. As you can see they are not simply a wire hanging down that lifts your boat up. They are more complex than that.

The individual strands are wrapped together as shown Then they are wrapped again around a core.

HOW DO CABLES GET DAMAGED?

There are two types of wear:

External abrasion

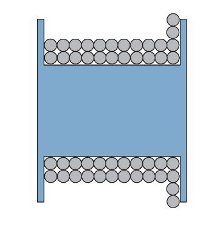

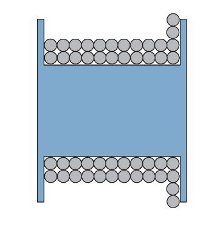

Typical Cable Stacking

This occurs when the cable bends around the winch drum and lift pulleys. On the winch drum, they rub against the adjoining wire or the drum sides. This rubbing causes wear on the external strands which will eventually wear through the individual stands.

If the cable doesn’t wrap properly, it starts to stack on the side of the winch drum. When the cable eventually slips off the “stack”, even though it is only dropping 1/4″ to 1/2″, the resulting noise shocks anyone nearby. It was under hundreds of pounds of pressure from the boat. This situation is usually caused by misalignment of the winch drum or a poorly threaded situation.

New ShoreMaster winches are attached with a complete housing around the upright post which prevents this from happening due to winch misalignment. More on this later in this discussion.

Internal abrasion

Internal abrasion occurs whenever strands work against each other under load. Each time a boat is raised or lowered over a winch drum, there is internal wear. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the strands is the result. When you lose too many strands, you lose a lot of strength. This condition cannot be eliminated but it can be controlled by using the proper size winch drum and pulleys.

A point often overlooked – internal abrasion and the resulting corrosion or rust in a galvanized cable, can be hidden and may not show visible damage. A cable like this may sometimes fail without prior warning.

ASSUMING IT IS WELL CARED FOR, HOW LONG SHOULD IT LAST?

Experts say that to be safe, replace a galvanized cable every two years. All things being equal, stainless wires will last longer-up to twice as long. But don’t rush out and try to change all your cables to stainless. Galvanized cable has its place on your lift. For one, they are stronger than stainless steel and can bend easier around the pulley and winch drum.

An improperly positioned boat may send your boat into the water. See https://wisconsinpws.com/boat-lift-safety-updated/ for more information.

When in doubt, replace the cable. Trying to squeeze another year out of the cable isn’t worth the risk of dropping your boat or personal injury.

COMMON PROBLEMS WITH BOAT LIFT CABLES

Frayed Boat Lift Cable

Chafe or fraying – are those fine broken strands that poke or cut your hands when you slide your hands along the cable. If you catch your clothes when they brush against a cable you have “chafe” or fraying.

Chafe may be the result of faulty sheave alignment or improper drum winding.

Lowering a lift rack without any weight on it, especially on a small lift like a PWC lift, may also result in a “backlash.” This is discussed later.

Note: Be aware that most winches require at least 50 lbs of weight to work correctly.

BROKEN STRANDS

Broken Strands

Broken strands are very dangerous. Boat lifts with this type of damage should be replaced immediately.

CORROSION

Corroded & Frayed Boat lift Cable

Corrosion presents a significant problem for galvanized cables. When the protective layer of galvanizing wears through as discussed above, corrosion will begin. Corrosion may not always be visible to the naked eye. The first time you become aware of the corrosion could be when the cable breaks.

Corrosion may also occur “inside” the cable with little or no external evidence of the damage as discussed above. Any cable showing external signs of rust or corrosion needs replacement.

BACKLASH

Boat lift cable backlash

When a lift is lowered to the bottom and the winch continues to move the result will be a Backlash. If there is insufficient tension on the cables they will “spring” in every direction on the winch drum. When you retighten the cable, the loose cables become snarled and can wrap up like a backlash in a fishing reel.

WHAT IF I EXPERIENCE A BACKLASH?

Whenever a cable experiences a backlash DO NOT use your bare hands to repair the problem (chafe). You won’t soon forget this if it happens to you. People have also lost fingers when a cable snaps back onto a winch drum. Make sure you wear leather gloves and keep tension on the cable at all times. Keep your hand at least 12″ from the winch to prevent entanglement.

When you experience a backlash, lower the boat into the water to prevent the cables from interleaving further on the drum.

Never use bare fingers or pliers to align the cables. As always, carefully handle it to avoid breakage of the wire strands.

Next, unwind the winch while keeping tension on it. Do this until you see the bottom layer on the drum. Re-wrap the cable onto the winch drum while maintaining tension. Rewind it in even layers. Be sure to close any gaps between the cable on the winch drum.

Finally, it is time to return your boat to the lift to raise it, making sure the cable continues to wind smoothly. If the problem persists, call your lift dealer (that’s PWS)

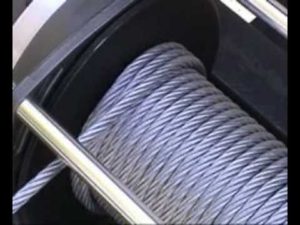

DID YOU REMEMBER THE WIRE “MEMORY”?

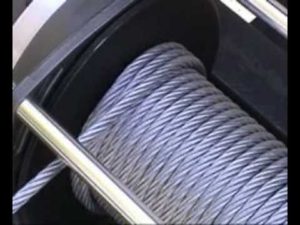

Properly wound cable

“Memory” allows the cable to play out and rewind onto the drum in a neat pattern. The wire must wind in a set pattern. Loose that “memory” and misalignment occurs which will cause the cable to turn against the side of the winch drum.

Maintain tension at all times to prevent the cable from interleafing with the windings in a lower layer. Fill in each layer completely, leaving no gaps.

WHAT’S COMING UP NEXT WEEK?

Next week we give you more information about boat lift cables and what you can do to lengthen their life.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts, and accessories.

We are located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection with Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 10, 2019

Thank you for all the work it took to install our boat slip. We really appreciate your help!

Jim B.

Aug 9, 2019

Thank you. …. Great Service

Sandi M.

Aug 6, 2019

WHY DOES MY DOCK SWAY?

Spring Storms

Dock sway is a result of deeper water and the need to raise your dock higher out of the water.

In 2016 we did an article about dock sway as a result of the high water that year. 2017 was worse, and 2018 continues this trend. The water depths have risen so much that each month brings new records. These records replace standards set years before many of us were born.

This year, in particular, we have experienced an unusual number of strong N.E. winds. These winds have resulted in the water depths you experience daily, to rise even further for a day or more.

These storm surges are the result of the bay being enclosed on three sides. There are limited rivers to dissipate the water at the south end when this happens. Those rivers are already at high levels and can’t dissipate more water.

Tall Ships

Recently the “Tall Ships” came to Green Bay, and some of the ships did not have enough room under the Tower Drive bridge near the mouth of the Fox river to pass under them. They had to wait until the winds changed to enter Green Bay for their exhibition.

For more information on the Tall Ships see https://tallshipswisconsin.com/event-description/

What can PWS do about Dock Sway?

To protect your dock as much as we can, we raise your dock higher to lessen the chance of storm damage. Many of you are aware of this because the dock legs were too short to allow us to raise your dock. Our Service Manager had to contact many people to enable us to take extra time to change the legs. Our installations, which were already slowed down by frequent rain and strong winds, got even slower.

Unfortunately, raising a dock moves the center of gravity higher, and it causes the dock to “sway” when you walk on it.

Here’s an example. If you step on a 6-foot step ladder, the first few rungs are stable. The higher you go – not so much. Place your feet on the top of the ladder, and you quickly realize you are in a precarious position. (Better start looking for a safe place to land.)

ShoreMaster docks, equipped with infinity leg pockets, extend the pockets to 18″ deep versus the usual 4″ – 6″ most docks have. Angled braces are added along with the pockets. Unfortunately, even this is not enough to prevent the sway some people are incurring.

Is there another solution?

Sway brace

There is a partial solution which helps but does not totally eliminate sway – the addition of sway braces to the legs.

The addition of one or more cross-braces will reduce the swaying motion. Cross braces are rigid pipe(s) attached at an angle to the legs of the dock. For the pier to sway at the top, it must also move the opposite leg at the base where it is firmer. Mounting sway braces lessens the amount of sway you experience.

If your dock is swaying too much for your comfort, please call John, our service manager, at 920-493-4405.

For sales, contact Jerry (Jerry@wisconsinpws.com) or call 920-493-4404.

Do you have a friend that might be interested in this post? Please forward it to them.

PWS is located at 7325 St. Hwy 57. That’s 1 mile North of County MM (Hwy 42) and 4 miles South of Sturgeon Bay at the Idlewild Road intersection.