Boatlift Cable Maintenance (Revisited)

Boatlift cables, properly maintained, will keep your boatlift functioning the way it is meant to operate. Perform a visual inspection of all cables, especially on the winch, on a regular basis.

The most frequent cause of issues with a boatlift involves a problem with the cables resulting from:

- Misalignment;

- Chafing (fraying);

- Corrosion (rust);

- Overloading;

- Improper Drum Winding; or

- Boatlift cables without tension

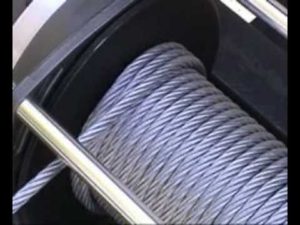

Properly wound boatlift cable

Cables must wind tightly and neatly on the winch drum as shown here.

Boatlift Cable improperly wound on the drum

Without tension on a cable, the cable unravels on the drum. The unraveling of the cable is like a “backlash” on a fishing reel. Re-winding the cable results in the cable winding against the side of the pulley drum. A loose winding of the cables allows an excess gap between the cable windings on the drum.

Boatlift Cable Backlash

When loose cables are re-tightened on the winch drum, they become flat, snagged or tangled. The result is uneven wear and damaged strands.

What if I experience a backlash?

Caution: Whenever a cable becomes jammed, there may have been an overrun (backlash) on the drum. DO NOT use your hands to repair the problem. People have lost fingers when a cable snaps back onto a winch drum.

Caution: If you are attempting to re-align the cables on the drum make sure to wear leather gloves and keep tension on the cable at all times. Keep your hand at least 12” from the winch. Broken cable strands cause painful cuts and punctures in your hands.

When you experience a backlash, lower the boat into the water to prevent the cables from interleaving on the drum.

Never use bare fingers to align the cables. As always, carefully handle the cable to avoid breakage of the wire strands.

Never use pliers to hold tension on the cable as this will damage individual strands on the cable.

Next, unwind the cable while keeping tension on it, until you see the bottom layer on the drum. Re-wrap the cable, under pressure, in even layers. Be sure to close any gaps between the cables on the winch drum.

Finally, it is time to return your boat to the lift to raise it making sure the cable continues to wind smoothly.

If the problem persists, call your lift dealer.

Don’t forget about cable “memory.

“Memory” allows the cable to plays out and rewind onto the drum in a neat pattern. The cable must wind in a set pattern. Loose that “memory” and misalignment occurs which will cause the cable to wind against the side of the winch drum.

This misaligned cable will drop off the “stack” and cause a loud, violent sound as it drops back onto the lower winding.

The cable must remain under tension at all times to prevent the cable from interleafing with the windings in a lower layer.

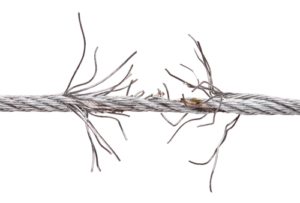

What is Boatlift Cable Chafe?

“Chafe” are those fine broken strands that cut your hands or catch your clothes when you slide your hands along the cable.

Chafe often results from faulty sheave alignment or improper drum winding. Lower a boatlift rack without any weight on it and the result will be a “backlash.” The backlash could result in additional damage to the cables.

Note: A lightweight jet ski rack may not go down as you unwind the cable with no weight on the lift rack. Be aware of this situation and try to keep constant tension on the cable at all times.

Boatlift Cable Corrosion

Corrosion presents a significant problem for galvanized cables. When the protective layer of galvanizing wears through, corrosion will begin. Corrosion may not always be visible to the naked eye. The first time you become aware of the corrosion may be when the cable breaks.

Corrosion may also occur inside the cable with little or no external evidence of damage.

Any cable showing external signs of rust or corrosion needs replacement.

Overloading and Boat Positioning

Make sure your boat is positioned correctly on the lift. If it’s not far enough forward, it will put excessive weight on the rear cables and the frame structure. The boat is also prone to washing off the lift in a storm from wave action.

Too far forward may damage the lower motor assembly or break the front cables due to excess weight.

In general, a boat has most of its weight at the stern. As a result, the stern should be about 12″ – 18″ from the lift rack. This position distributes the weight evenly across the lift rack and prevents overloading the cable system.

What Cable Maintenance am I able to perform myself?

A visual inspection of the cables needs to occur on a regular basis. It is helpful to do this when the lift rack is in its lowest position. In this situation, most of the cable is available for inspection. Look for chafing, corrosion or flat cable especially near the winch box.

Don’t forget – do this inspection with leather gloves on to protect your hands. At the beginning of the boating season, be sure to apply a short burst of penetrating oil to the top of the cables wrapped on the winch drum. The penetrating oil will work its way down the cable as needed.

Boatlift Cable Lubricant

Do not be afraid to do it more often during the summer months, if you use the boatlift a lot.

Never apply grease to the cables. Grease prevents the moisture from escaping the cable and winch drum. Most quality lifts use Stainless Steel cables for a majority of cables and (1) galvanized cable as the winch cable. Trapping moisture in the cables causes them to corrode faster.

To summarize, take care of your cables, and they will last for years.

Where can you find Pier & Waterfront Solutions?

We are located in the center of the Door County Peninsula at 7325 St. Hwy 42/57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Our staff is always ready to serve your needs.

Don’t forget – Give us a call If you have a dock or boatlift topic you would like to see addressed on our site,

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.