Sep 12, 2017

Boat Lift Cables Require Maintenance

Boat Lift cables, along with the winch on your lift, are the (2) most important components of a boat lift. As a result, they require periodic attention. Remember, these (2) pieces do all the “work” on your lift. They do the lifting by raising the rack assembly with the weight of the watercraft on it. Lift cables allow your boat, pontoon or PWC to be raised and lowered when you need them.

The lift cables are made of either stainless or galvanized steel.

Both types of steel offer the benefit of corrosion resistance and strength. But there are some noteworthy differences that you need to pay attention to if you are deciding on a new or used lift or just plain replacing the cables.

You need to look at the available options and be able to do simple maintenance on either type of cable. With your owner’s manual, the correct part number, weight capacity, and type of cable should be listed. If it is not listed, or you do not have an owner’s manual, you can contact PWS to get assistance in determining what cables your lift requires regardless of the brand. PWS can get the correct cables so the cables can be replaced correctly.

Types of Steel used as Boat Lift Cables

Galvanized Steel: Galvanized steel is a carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. This is accomplished through a “hot dip” in a zinc bath. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is strong and each cable is made to handle the loads created by your boat lift. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium in the steel forms a thin layer of chromium oxide that promotes resistance to corrosion. When exposes to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium simply oxygen to maintain this property of resistance.

Getting technical now

Galvanized steel boat lift cables, although corrosion resistant, are more prone to wear. The zinc layer can be scratched or cracked through expansion and contraction. This can lead to spot rusting and a decreased life of the steel cable. The scratching occurs when a cable rubs against itself as it winds around the winch drum. Each layer is going at a slightly different speed than the layer below it – thus scratching the zinc coating on the cable.

Even internally the strands in the cable are rotating at a different speed and the zinc will be damaged. This can be frequently seen on the upper areas of a galvanized cable where it enters the winch. It also frequently occurs on the bottom layer of a cable where it is wrapped around the drum on the winch.

Stainless steel boat lift cables, on the other hand, are blended with chromium oxide during manufacturing. This makes its corrosion resistance regenerative in fresh water.

Rusted Boat Lift Cables

You will see lift cable corrosion most commonly in the form of rust.

Galvanized steel cables will corrode over larger areas of its surface while stainless steel cables seldom rust. The addition of chromium to the steel during the production process creates a product that is regenerative and uniform in resistance throughout.

Whereas galvanized steel, with its zinc coating, does not regenerate and when damaged exposes the steel beneath to the elements. The rusted areas are more prone to fraying and breakage too.

In Conclusion … Follow these Maintenance Suggestions for your Boat Lift:

- In spring and fall (and at least once during the summer months), put a short blast or two of PENETRATING OIL on the cables wrapped around the winch drum from the top of the winch. Do not soak the cable, you’ll contaminate the water below. DO NOT use any oil except penetrating oil. NEVER USE GREASE (it traps the moisture inside the cable accelerating it’s deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed, if corrosion is present.

- Check all cables to make sure they’re aligned properly on the pulleys

- With your watercraft on the rack – check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack fully down (but without slack in the lifting cables.)

- If the canopy cover is on, are all the springs or bungee cords secured? Broken hardware should be immediately replaced.

- Check bunks and guides to make sure the hardware is secure.

- If carpeted, replace torn bunk and guide fabrics to protect your boat hull. Consider replacing carpet with vinyl bunks.

- Exterior wheel driven winch? Check the bungee cord to see if it needs replacement. Cracked cords can break at any time so be sure to use the correct cord. Contact PWS for replacements.

- Don’t ignore your dock – check the bolts. Are they secure ?

It is our hope that this article will make your decision easier and lend more confidence to your selection. Your boat lift is an investment and as such we want to make certain that we help you make a wise decision.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 8, 2017

Dock Bumpers Protect your Investment

Dock bumpers protect your boat and dock from damage. You have a major investment in your boat and dock system. Dock bumpers go a long way to protect that investment. The bumpers come in several styles. The selection of the correct one for you is basically determined by your location.

Rivers and Lakes

Docks installed less than 18″ above the water level will allow the use of horizontal side bumpers. These bumpers will work for you, unless you experience waves over 18″ or have large water depth fluctuations. Horizontal side bumpers are available in several configurations.

Horizontal Side Bumpers

Dock Side Bumper

A side bumper wraps over the top and/or upper part of the dock frame. and are made in 10′ lengths. The sections are cut to accommodate posts and accessories. The side bumper may be cut to conform to the size of the deck panels for ease of winter removal. The bumper protects the hull of the boat from hitting the top and side of the dock. Normally, it is not applied to the bottom of the dock frame..

Corner Bumpers

Dock Corner Bumper

The corner bumpers are made from the same material as the side bumpers. It is factory formed into a right angle to protect the boat hull from two directions at the corner of a dock. Mounted at the end of the dock, they measure approximately 12” in each direction.

Dock Corner Wheel

An alternative is a vinyl wheel which mounts at a corner. This wheel rolls horizontally around the corner to guide and protect the boat hull.

The wheel does take up about 6″-*8″ of deck space in the corner. It will not be effective if you have large waves. You may be under or over the wheel and need a bumper that allows the boat to go up and down.

Large Lakes and the Bay of Green Bay

Vertical Bumpers must be used on larger bodies of water like the Bay of Green Bay and Lake Winnebago. They experience water fluctuations larger than 12″ and wave action exceeding three feet. This is particularly important when the dock is set high to accommodate wave action. This type of bumper will help prevent you boat from going under the dock frame.

Vertical Dock Bumper

Docks set over 24” above the water have a unique problem. If the side of the boat moves under the frame of the dock it will cause severe damage to the boat. A horizontal side bumper can not prevent this type of damage.

3′ high vertical dock bumpers prevent the boat from moving under the dock frame when in the trough of a wave.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Check out our Facebook page at “Pier & Waterfront Solutions.”

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Coming Soon – “The PWS Store” on our website

Jul 18, 2017

Plastic Decking is a Major Investment

Plastic decking on a dock or deck is a major portion of the your investment. It makes sense to take time to maintain it properly. This is particularly important on marine structures vulnerable to the elements. All plastic decking requires some yearly maintenance to remain attractive for years to come.

What causes my Plastic Decking to appear dirty?

Mold/mildew is the common term used to describe a growth on the surface of matter. It’s caused by fungi, especially in the presence of dampness. Under a microscope, mold has an octopus-like structure. Its legs attach to a surface in a web-like manner. Once mold has successfully colonized, it releases thousands of new spores over and over again. This growth makes your plastic decking appear dirty.

What makes the mold grow?

Mold needs three things to grow:

- Food, (Leftovers from a bird’s diet and their “droppings” provide the “menu” mold needs to thrive.)

- Moisture (rainwater and people walking on the dock) and

- Temperate weather.

When the spores are in the favorable environment described above, they will germinate. The spores settle out of the air or are deposited by rainwater and wet feet. As a result, they will be more prevalent on horizontal surfaces (like your dock panels). The colonies do not migrate, but rather establish colonies and release even more spores.

Plastic decking is inorganic but nature deposits “food” and moisture in the form of rainwater. Birds deposit further nutrients and even you carry moisture, suntan lotions and dirt from the environment and deposit it on the decking.

While plastic surfaces appear sleek and impermeable, plastic decking still cannot escape the mold/mildew cycle. Plastic decking needs to be cleaned at least once/year. This is particularly true with HDPE plastic decking (usually recycled, solid plastic boards) used as plastic decking,

How can I clean the mold and other dirt off my decking without chemicals?

We all know that we must avoid introducing pollutants, including soaps and cleaning products into our waterways. Still, you do have an option.

With Plastic Decking it usually is not necessary to use ANY chemical cleaners. If you must use a cleaner be sure to use natural biodegradable cleaning solutions that removes buildup without damaging the environment.

Using a Pressure Washer on Plastic Decking makes it super easy to clean

Note – In all cases, the use of safety gloves, face masks or eye protection is highly recommended. Bare feet and hands are very vulnerable to pressure washers and chemicals. Serious injury can occur.

Remember- No chemicals are needed with a pressure washer on Plastic Decking.

With a pressure washer, use a “fan” nozzle with a 20 – 40 degree tip to reduce the pressure. Never use more than 1800# of pressure. The less pressure at the sprayer head, generally the better.

Sweeping across plastic decking in either direction is very effective even without the use of chemicals.

Hand scrubbing

Using a hand brush with natural or plastic bristles and a commercially available product like “OxiClean” is a safe way to wash the decking. “OxiClean” breaks down to oxygen, water and soda ash so it won’t harm the environment. “OxiClean” uses oxygen ions to neutralize stains and dirt.

Many scrub brushes allow you to use a pole handle. This way you do not have to kneel down and it will be more comfortable for you.

Do not press so hard that the bristle bend to the side as the real cleaning takes place at the ends of the bristles. If there is a wood-like or knurled pattern in the decking surface try to follow that direction. This allows you to get deeper into the grooves with less effort.

Get into the deck spacing as far as possible to make the decking look even better. Before the decking dries, rinse the decking with clear water.

If the product you plan to use has oxalic acid (very corrosive) or chlorine bleach we strongly recommend that you do not use it. It is not biodegradable and It could also get you a major fine from the DNR.

As an extra caution, check the label of any product you plan to use to see if it contains harmful ingredients like hypochlorite bleach.

Remember

Pier & Waterfront Solutions (PWS) is located in the center of Door County at 7325 St Hwy 57, south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

. Coming Soon – “The PWS Store” on our website.

Jul 10, 2017

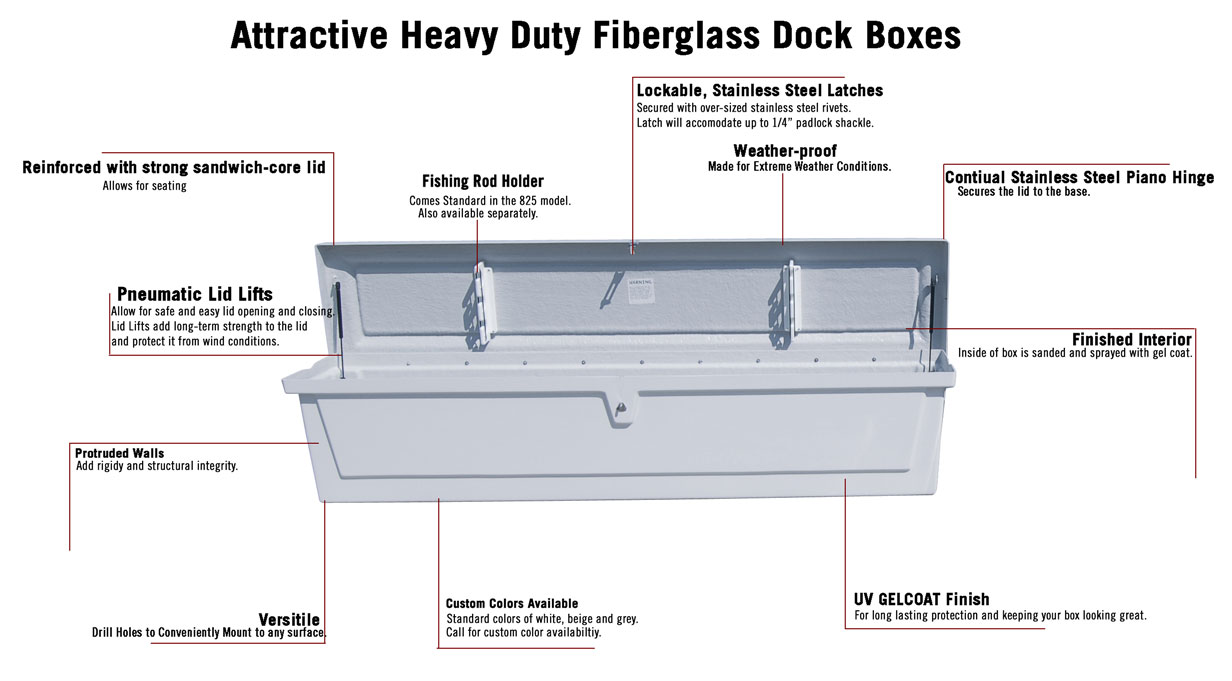

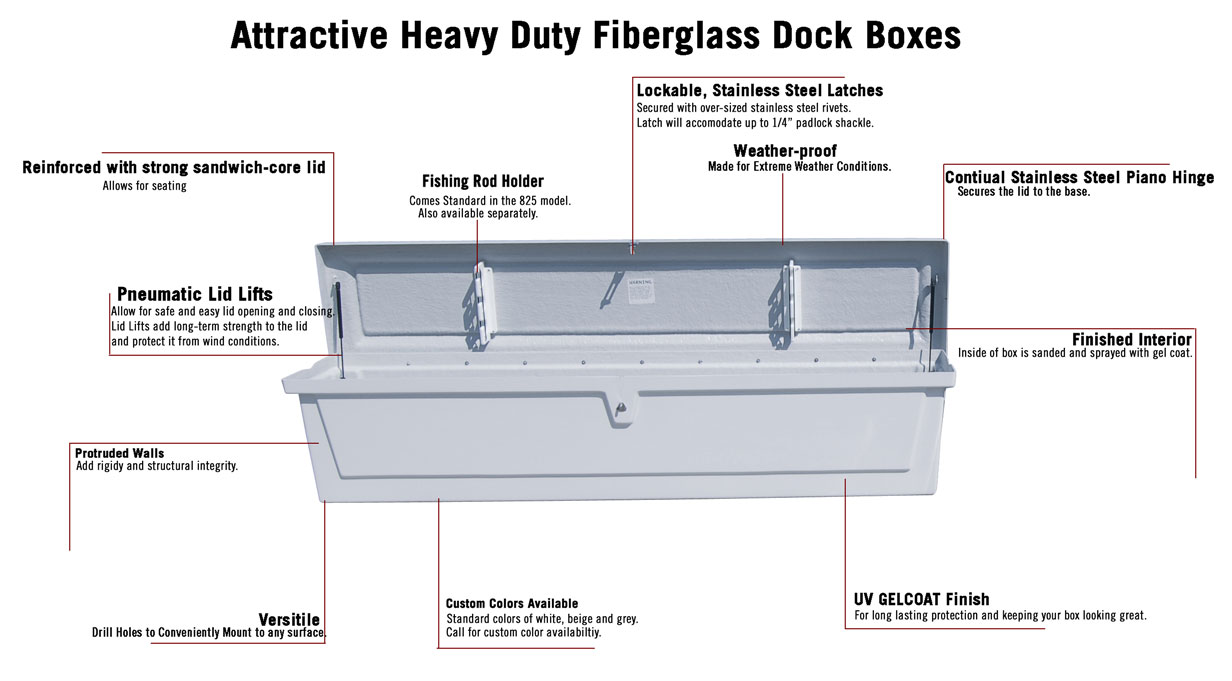

WHY A DOCK BOX?

A dock box is an easy way to have everything securely stored right at your fingertips. Getting tired of carrying everything from the house to the dock and then back again? You do not have to carry it back and forth every time you want something. The Dock box is ready when you are.

Lift vests, water toys, towels, water skis, etc can all be ready on a moment’s notice. It’s a great way to keep things safe and dry.

Dock boxes are available in over 20 different sizes and styles including seated versions and stand up lockers. Go to .dockboxes.com to see the various sizes and styles available. Then call PWS for a installed price quote.

Assorted Dock Boxes

Check out the features of a quality dock box.

Dock Box

Note: Not all features available on all sizes or units.

Other uses for a dock box or locker box

Dock Box seat

Keep your yard neat by installing a dock box or locker storage unit on your lawn, on your deck or even under your deck Store the kids toys safe and secure with no unsightly mess for the neighbors to see.

The contents are safe & secure while you are gone. A dock box seat gives you extra storage and seating on your deck

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster and Dock Boxes Unlimited accessories for docks and lifts. PWS is located in the center of Door County at 7325 St Hwy 57 south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

. Coming Soon – “The PWS Store” on our website.

Jul 5, 2017

Kids of all ages love a slide in the water

With that in mind, you can provide entertainment and a lot of excitement for the kids this summer with a slide that empties into the water! They will really enjoy the fun all summer long. Who doesn’t enjoy a slide?

FreeStanding slide

This freestanding model has adjustable legs so you can set the height above the water. In addition, the handrails provide extra security and stability for the kids. Imagine the fun they will have!

They’ll line up to be the first one to go down! Your problem will be how to get them out of the water!

The aluminum frame and brightly colored slide (Yellow or Tan) is maintenance free and a joy to use.

What other options are there?

Dock Mounted Slide

There is more than one option available. The slide can be mounted on a dock or raft for even more fun and excitement. Talk to PWS about the slides and/or the dock or raft to mount it on.

.

NOTE – PWS wants a safe environment for your family. Make sure there is enough water depth to protect the family when exiting the slide. Clear all boulders and hard surfaces from the area to prevent injury. Make sure the unit is stable before anyone uses it. This applies to dock mounted or Freestanding models.

Kids should be supervised at all times.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster accessories for docks and lifts. Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also..

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

. Coming Soon – “The PWS Store” on our website.