Mar 17, 2020

Wire Rope Lubricants

Wire rope lubrication is critical to extending the life of a cable (often referred to as the “lift cable”). How significant is it? Failure to complete this simple maintenance can reduce wire rope life by up to 50%.

Tell me more!

A wire rope consists of wire strands wound around a central core, then again wound around themselves to form a wire rope. The center may consist of steel or even plastics. Here are just some of the MANY different configurations for a wire rope.

Wire Rope Configurations

The use of a small strand size is better suited to bending around small sheaves (pulleys). Taken to an extreme, a wire made of one thick “strand” would not be able to go around a pulley.

Many small strands allow the wire rope to bend easily around the pulleys. In doing so, the strands “rub” against each other, causing friction. Over time, friction rubs any external coatings off the wire rope.

How are the wire rope strands protected against rust?

Uncoated wire rope strands left “uncoated” will rust from exposure to moisture in the air;

The cable strands get a coating of zinc for rust protection (called galvanizing). The steel strands travel through a hot zinc bath to coat the surface with rust protection. The “con” to galvanized cables – the surface does not regenerate when damaged.

What about stainless steel cables?

In simplest terms, when molten high carbon steel mixes with chromium, it forms stainless steel. When in contact with air, the chrome restores the anti-rust properties. The “con” side – it gives up small amounts of strength.

What function does lubricating a wire rope perform?

Wire rope lubricants;

1. Reduce friction in the layers of the wire rope as they move over other layers. It’s true for galvanized & stainless steel cables both; and

2. Lubricants provide corrosion protection and lubrication in the core of the cable. Less rust and friction means longer life for the cables.

Are there different lubricants used?

Boat Lift Cable Lubrication

There are different types of wire rope lubricants – penetrating and coating. Solvents in penetrating oils carry a lubricant into the core of the wire rope. When the solvent evaporates, it leaves behind a lubricating film to protect the strands.

“Coating” lubricants (grease) barely penetrate a cable. The coating seals the outside of the cable from moisture and reduces wear and corrosion. But, it also seals moisture inside the cable, thus promoting the rusting process.

PWS recommends only penetrating lubricants.

Most wire ropes fail on the inside first. It is vital to ensure that the center core receives enough lubrication. Repeated applications over a day are a good idea.

It is best to apply short bursts of spray lubricant on the top cables wound around the drum. Spray across the top of the wires to get the best penetration and protection. The rope strands tend to separate slightly due to bending around the winch drum. This separation allows the lubricant better access to the core of the wire rope.

Four Rules to follow:

- Do not apply a grease lubricant on a boat lift cable;

- Never change the diameter of the lift cable;

- Never substitute a different wire construction; and

- Do not replace stainless steel cables with galvanized cables.

Experience suggests that life cycles may double with lubrication. But remember, there are other factors affecting wire rope life also.

PWS attributes the increase in the life cycle to the use of penetrating oil to displace water and decrease friction. The oil reduces the wear and corrosion occurring inside the rope. Spraying with a penetrating lubricant acts like an oil change for cars. You’d never allow your vehicle to run out of oil. Right?

The savings from lubrication versus replacing a lift cable are considerable.

What else can damage a boat lift cable?

Improper winding and shock loading with heavy loads damage the cables. These actions will speed up wear and corrosion. See this link.

WHAT ABOUT MY BOAT LIFT?

In a previous post, we explained the danger to boat lift cables if the waves hit the bottom of your boat. We also demonstrated what defective wires look.

7 x 7 cable construction

Rust on galvanized cable

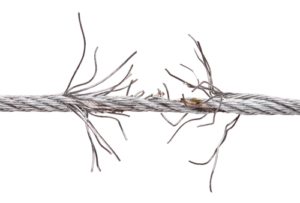

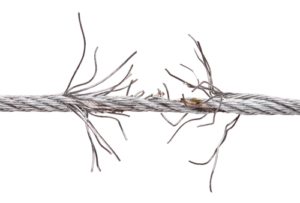

Once again, here are the warning signs of defects in your cables.

Broken Strands

If your cable looks like any of these, it’s time to replace them.

Warning – It is possible to break strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust. If you see “rust” on a stainless steel cable, it is from the winch drum depositing rust in the winding process.

Visit Pier & Waterfront Solutions on Facebook also.

Tell Your Friends & Family

Have friends or neighbors you believe would like to see this article? Email them this link – they’ll thank you!

Where is PWS?

You will find us at the intersection of Idlewild Road and Hwy 57 in Door County. The address is 7325 St. Hwy 57, Sturgeon Bay. That’s 3 miles south of Sturgeon Bay, and 1 mile north of the intersection with Cty MM.

Our staff looks forward to serving ALL your waterfront needs.

Contact:

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – erosion control and shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – commercial work and new & used Sales.

John @ (920) 493- 4405 or John@wisconsinpws.com – Scheduling & Service work.

Jul 17, 2018

Nothing lasts forever – including boat lift cables

Boat Lift cable problems require a thorough explanation.

There are two types of normal cable wear:

- Internal cable abrasion- This occurs whenever strands work against each other under load.

- External abrasion – This will occur when the cable bends around the winch drum and rubs against the adjoining cable wrap. It also occurs when the cable rubs against the side of the winch drum

Frayed Boat Lift Cable

Types of Steel used as a Boat Lift Cable

Galvanized Steel: Galvanized steel is carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. A “hot dip” in a molten zinc bath results in galvanizing the cable. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is stronger than stainless steel. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium forms a chromium oxide layer that promotes resistance to corrosion. When exposed to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium merely needs oxygen to maintain this property of resistance.

All Lift Cables Will Require some Maintenance

The winch and lift cables require periodic attention. Remember, these (2) items do all the “work” on your lift. They do the lifting of the rack assembly with the weight of the entire boat and motor on it.

Boat lift cables are manufactured out of either stainless or galvanized steel.

Galvanized cable is used as the winch cable on heavy boats. Stainless steel cables are used for the remaining cables on top brands like ShoreMaster.

Both types of steel offer the benefit of corrosion resistance and strength. However, watch for the noteworthy differences mentioned above that require your attention.

Corrosion

Galvanized cables that break usually show signs of corrosion or rust in advance. Typically, the failure is located near the winch when the rack is in a lowered position. Another common site for corrosion is at the bottom of the cable where it secures to the frame on some brands.

Rusted Boat Lift Cable

A slight discoloration indicates that the protective galvanizing coating may have worn away. Heavy concentrations of rust indicate that the steel cable is losing strength and requires replacement immediately.

How long should a cable last?

Experts claim galvanized cables require replacement every two years. All things being equal, a stainless cable will last up to twice as long.

A point often overlooked – internal abrasion or rust is hidden and may not show external damage on the cable during a visual inspection. A boat lift cable like this may sometimes fail without prior warning.

Other causes of cable failure

An improperly positioned boat puts extra strain on any boat lift cable. Wave action pounding against the boat hull or jamming the rack against the frame may send your boat into the water with a corroded or damaged cable. Even a new cable may “snap” if you jam the rack against the frame.

When in doubt, replace the cable; trying to squeeze another year out of a $95 cable that you know s damaged or rusting isn’t worth the risk.

In Conclusion… What Can You Do For Your Boat Lift Cable?

- In spring and fall put a short blast or two of PENETRATING OIL on the cables. Spray the cables wrapped around the winch drum from the top of the winch. Do not soak the cable; you’ll only contaminate the water. Use only penetrating oil. A quick spray during the summer is very helpful.

- NEVER USE GREASE to lubricate the cables. (grease traps the moisture inside the cable accelerating its deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed.

- Check all cables to assure correct alignment on the rack pulleys.

- With your boat correctly positioned on the lift, check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack all the way down. Maintain weight on the rack to assure proper tension on the cables.

We hope that this article will make your life easier and lend more confidence to your selections. Your boat lift is an investment, and as such we want to help you make wise decisions.

Reminder

PWS is located in the center of Door County at 7325 St Hwy 57. It is located 1 mile North of County MM (Hwy 42) and South of Sturgeon Bay. Look for the intersection of Idlewild Road.

Want us to address a dock or boat lift topic for you? Feel free to give us a call.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Sep 12, 2017

Boat Lift Cables Require Maintenance

Boat Lift cables, along with the winch on your lift, are the (2) most important components of a boat lift. As a result, they require periodic attention. Remember, these (2) pieces do all the “work” on your lift. They do the lifting by raising the rack assembly with the weight of the watercraft on it. Lift cables allow your boat, pontoon or PWC to be raised and lowered when you need them.

The lift cables are made of either stainless or galvanized steel.

Both types of steel offer the benefit of corrosion resistance and strength. But there are some noteworthy differences that you need to pay attention to if you are deciding on a new or used lift or just plain replacing the cables.

You need to look at the available options and be able to do simple maintenance on either type of cable. With your owner’s manual, the correct part number, weight capacity, and type of cable should be listed. If it is not listed, or you do not have an owner’s manual, you can contact PWS to get assistance in determining what cables your lift requires regardless of the brand. PWS can get the correct cables so the cables can be replaced correctly.

Types of Steel used as Boat Lift Cables

Galvanized Steel: Galvanized steel is a carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. This is accomplished through a “hot dip” in a zinc bath. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is strong and each cable is made to handle the loads created by your boat lift. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium in the steel forms a thin layer of chromium oxide that promotes resistance to corrosion. When exposes to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium simply oxygen to maintain this property of resistance.

Getting technical now

Galvanized steel boat lift cables, although corrosion resistant, are more prone to wear. The zinc layer can be scratched or cracked through expansion and contraction. This can lead to spot rusting and a decreased life of the steel cable. The scratching occurs when a cable rubs against itself as it winds around the winch drum. Each layer is going at a slightly different speed than the layer below it – thus scratching the zinc coating on the cable.

Even internally the strands in the cable are rotating at a different speed and the zinc will be damaged. This can be frequently seen on the upper areas of a galvanized cable where it enters the winch. It also frequently occurs on the bottom layer of a cable where it is wrapped around the drum on the winch.

Stainless steel boat lift cables, on the other hand, are blended with chromium oxide during manufacturing. This makes its corrosion resistance regenerative in fresh water.

Rusted Boat Lift Cables

You will see lift cable corrosion most commonly in the form of rust.

Galvanized steel cables will corrode over larger areas of its surface while stainless steel cables seldom rust. The addition of chromium to the steel during the production process creates a product that is regenerative and uniform in resistance throughout.

Whereas galvanized steel, with its zinc coating, does not regenerate and when damaged exposes the steel beneath to the elements. The rusted areas are more prone to fraying and breakage too.

In Conclusion … Follow these Maintenance Suggestions for your Boat Lift:

- In spring and fall (and at least once during the summer months), put a short blast or two of PENETRATING OIL on the cables wrapped around the winch drum from the top of the winch. Do not soak the cable, you’ll contaminate the water below. DO NOT use any oil except penetrating oil. NEVER USE GREASE (it traps the moisture inside the cable accelerating it’s deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed, if corrosion is present.

- Check all cables to make sure they’re aligned properly on the pulleys

- With your watercraft on the rack – check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack fully down (but without slack in the lifting cables.)

- If the canopy cover is on, are all the springs or bungee cords secured? Broken hardware should be immediately replaced.

- Check bunks and guides to make sure the hardware is secure.

- If carpeted, replace torn bunk and guide fabrics to protect your boat hull. Consider replacing carpet with vinyl bunks.

- Exterior wheel driven winch? Check the bungee cord to see if it needs replacement. Cracked cords can break at any time so be sure to use the correct cord. Contact PWS for replacements.

- Don’t ignore your dock – check the bolts. Are they secure ?

It is our hope that this article will make your decision easier and lend more confidence to your selection. Your boat lift is an investment and as such we want to make certain that we help you make a wise decision.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 2, 2017

When Should A Boat Lift Cable Be Replaced?

The proper time to replace a boat lift cable depends on a variety of circumstances:

Corroded & Frayed Cable

- How well is it maintained?

- How often is it lubricated?

- What is used to lubricate the cables?

- Is the cable winding properly?

- Was the lift sized properly?

- Is there any visual damage to the cable?

- Are there frayed wires on the cable?

- Is it a galvanized cable or stainless steel?

- Is there corrosion on the cable?

What is the proper lift cable maintenance?

Lift cable replacement depends on a visual inspection of the lift cables to help determine when to replace them. It’s best to inspect it while it is on dry land in order to check all of the key points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Frayed Lift Cable

Examine the vertical length of the cable for frayed wires especially near the winch. CAUTION – Always wear leather gloves when sliding your hands on the cable. To put it differently, a frayed wire can cause extensive, painful damage to unprotected hands.

The cable is made up of multiple strands of wire and multiple wraps are used to form the overall cable. Excessive fraying or corrosion near the winch is a top signal of damage.

Nothing lasts forever – even boat lift cables

There are two types of cable wear:

- Internal cable abrasion- This occurs whenever strands work against each other under load.

- External abrasion – This also occurs when the cable bends around the winch drum and rubs against the adjoining cable or drum.

How long a lift cable lasts depends on:

- How often it’s used;

- What type of cable it is; and

- The care it receives.

Every time a boat is raised or lowered over a winch drum there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When you loose too many strands you lose a lot of strength.

What should be done?

Steel lift cables require a squirt or two of penetrating oil occasionally to reduce the internal friction on the strands and individual wires in the cable. This is particularly important on galvanized cables. Lubrication helps to preserve the galvanized coating and minimizes abrasion between strands. Grease should NEVER be used, as it traps moisture inside the strands. Do not saturate the cable and only use penetrating oil for best results.

Stainless steel lift cable will also benefit from a few squirts of penetrating oil. This should be done in Spring and again in Fall.

Strong indicators that a boat lift cable needs to be replaced:

- Excessive broken strands:

- Kinks:

- Deformities and

- Areas of heavy corrosion.

Corrosion

Rusted Lift Cable

Galvanized cables that break tend to show signs of corrosion or rust. Usually this is located near the winch when the rack is in the lowered position. It also can be at the bottom of the cable where it is secured to the frame. Note: do not allow the main cable to go “slack” when lowering the rack.

A slight discoloration indicates that the protective galvanizing coating has been worn away. Concentrations of heavy rust indicate that the steel cable itself has lost considerable strength and should be replaced immediately.

Assuming the cable is well cared for, how long should it last?

Experts say that, to be safe, galvanized cable should be replaced every two years. All things being equal, stainless cable will last longer, up to twice as long.

A point often overlooked – internal abrasion or rust can be hidden and may not show visible damage on the cable. A boat lift cable like this may sometimes fail without prior warning. An improperly positioned boat, shocks from wave action (when bouncing on the lift rack or jamming the rack against the frame may send your boat into the water.

When in doubt, replace the cable; trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Coming Soon – “The PWS Store” on our website