Feb 19, 2019

WHAT SIZE BOATLIFT DO I NEED?

What size boatlift do you need? Purchasing a new boatlift does not have to be a confusing time. Yet, you have a lot to consider before making your final decision. By spending a little time here, you will be better educated and able to ask the right questions. Ultimately it will ensure you make a better choice.

In addition to getting the numbers, here are some things to consider:

How big is the body of water you will be on?

For instance, will you be on the bay of Green Bay, Lake Winnebago or are you on an inland lake or river? In general, the larger the body of water, the larger the waves will be and the higher your boat must be.

Are there significant fluctuations in water depth during the boating season?

Green Bay and Lake Winnebago present unique situations for boaters because these two bodies of water have substantial variations in water depth and wave action every year. Why are these fluctuations so significant?

When these two situations combine, you want a lift that puts your boat well above the water, so your investment is safe.

How about the boatlift frame construction?

You need a durable frame construction to withstand the boat weight and pressures from the waveWelded side frames prevent any lateral movement in the lift. With age, every time you put your boat on them, bolted side frames move laterally. This will eventually result in enlarged bolt holes, rusted bolts, and loose nuts from the movement of the side frames.

Welded Areas on Side Frames

Compare to other manufacturers

Most brands use bolts everywhere, so shipping is less expensive. The more bolts used in the side frames, the weaker the entire structure is. By comparison, the ShoreMaster boatlift with welded side frames prevents lateral movement.

Only ShoreMaster boatlifts have a welded “V” frame to make access to your boat easier. You do not have to crawl over a horizontal bar to get into your boat.

What is the gauge (material thickness) of the Frame?

The best-constructed boatlifts have aluminum, welded frames using heavy gauge, square or rectangular aluminum. Round vertical legs are not as strong as a square or rectangular leg. As a result, with structurally welded frames and the heaviest gauge tubing, you have the most durable frames possible. We urge you to compare ShoreMaster lifts with any other brand.

What material is used for the pulley?

No matter what size boatlift you purchase pulley material is a critical maintenance issue for any boatlift. Most manufacturers use plastic pulleys because they are cheaper to make. On the other hand, they get brittle over time. The sides of the groove tend to crack and break off allowing the cable to fall out of the pulley. If the cable is already weakened due to rust or broken strands, the cable may break.

Plastic Pulleys

However, if the cable does not break, two things can happen:

- The cable may jam between the pulley and the tube side. As a result, it will become very difficult to raise or even lower the boat. or

- The cable may drag across the pulley shaft. This will put an excessive drag on the cable and eventually wear a groove in the shaft until it breaks the shaft off.

Brass Pulleys

ShoreMaster uses brass pulleys with stainless steel bushings for unsurpassed strength. They simply NEVER wear out or break. Even the smaller jet ski lifts use brass pulleys to minimize maintenance issues.

What is the most popular boatlift used on the Door County Peninsula?

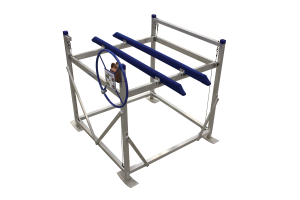

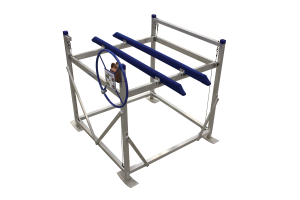

Vertical Boat Lift

The VERTICAL boat lift is the most popular boat lift in Door Couty. It far surpasses the cantilever boatlifts used in the past.

Vertical boatlifts require less water – 6″ vs 12″. They also raise your boat higher. Normal cantilever boatlifts raise your boat 36″ – 40″ high versus a vertical lift which goes to 66″ high. Vertical lifts have capacities up to 7,000 lb.

What is the warranty of the boatlift frame?

Some boatlifts come with a 1 or 2-year factory structural warranty. Some have a five year, and a few have a 10-year warranty. ShoreMaster boatlifts carry a full 15-year structural warranty.

Don’t you deserve the best protection and strength of a ShoreMaster Boatlift?

In Part 4 of this series, the discussion will be the actual calculations to select the correct size boatlift.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Please share a link to this article with them.

PWS is located at 7325 St. Hwy 42/57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection

Our staff is here year-round to assist you.

Feb 8, 2019

Thank you, Jerry:

Really appreciated your dock & pier services. Your guys did a great job and I can not wait to get it (lift) in the water.

Thanks again Jerry and if we need anything I will call you

Jim J.

Wisconsin

Feb 5, 2019

WHAT SIZE BOAT LIFT DO I NEED?

A boatlift can come in several styles. In this first of a four-part series, we discuss Cantilever, PWC, ShorePorts, and Track systems.

Each boatlift has a specific way it operates, and the conditions under which it should be used. We’ve narrowed the selections down to (8) different types of boat lifts and PWC lifts used most often in N.E. Wisconsin. The more you know about them the more confident your purchasing decision will be.

Cantilever Boatlift

A cantilever lift is generally suitable if you are on a moderate depth inland lake. If the water depth does not fluctuate more than 12” in a boating season, a cantilever lift may work for you.

Cantilever Boatlift by ShoreMaster

Cantilever boatlifts require more water depth than a Vertical lift – (usually 12” of water versus 6″). The lifting rack does not lower into the water as far as other options. Plus, you still have to allow enough water above the lift rack to float your boat on it.

Additionally, they generally have a lifting height of 30” to 40” which is too low for the bay of Green Bay. What if you have waves of 36” or higher or a water surge. Your boat is in danger of getting washed off the rack.

Due to these limitations, a cantilever boat lift is not used on the Door County Peninsula very often. These limitations also mean the resale value is going to be less.

PWC Lift

Vertical PWC Lift by ShoreMaster

PWC (Jet Ski lifts) come in 2 styles: Vertical and Floating. (We have excluded the Cantilever lifts.)

ShoreMaster’s vertical PWC lifts allow you to get into shallow water and raises your boat 50″ high. It operates in the same fashion as a standard vertical boat lift. It provides excellent protection for your PWC.

ShoreMaster PWC Lift

ShorePort

ShorePort PWC Lift by ShoreMaster

ShoreMaster’s Floating lifts (ShorePort) are excellent on rivers that fluctuate in depth, or marinas and inland lakes. They are very simple to use and need very little water to operate. The floating lift requires no maintenance, and you simply drive up onto it. No need to have a motor or crank a wheel.

Wave action above 15” is not recommended for this type of “boatlift.” Combine a floating PolyDock with the PWC floating lift, for the perfect combination on a lake or river.

Track or Ramp System

Roll-n-Go Boat Ramp

Roll-n-Go PWC Track System

The track or ramp system is still another option. The personal watercraft ramp comes with a 25-foot nylon loop and winch which prevents scratching while loading the PWC. The basic unit measures 11′ long. There are optional 8′ and 30″ extensions to increase the length of your ramp. How about an adjustable 11″ – 14″ width which accommodates even the largest jet skis.

Basic ramps are available with capacities of 750 lb up to 2,000 lb capacity. See Also: http://roll-n-go.com/

The Track system works best when the supports can be anchored into the ground. Without anchoring, the tracks can move by wave action and the result is a twisted frame. These are ideal for inland lakes when only the basic length is needed, as shown above, and the track is secured.

The PWC or boat can be hand operated or a Lift Boss motor option is available.

Lift Boss

In part 2 of this series we discuss three more options: Hydraulic boatlifts, Elevator lifts, and Floating lifts.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Please share a link to this article with them.

PWS is located at 7325 State Hwy 57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection. Our staff is here year-round to assist you.

Jul 31, 2018

Boat safety

Boat safety should be part of Wisconsin’s three great seasons for boating. Yes, 3 seasons and then comes winter!

Boat SafetyTips

Boat Safety Rule #1- Everyone needs one

- Life Jackets are Mandatory: We all understand that life jackets can save lives. But so many of us don’t bother wearing them when we hit the water. Whether you don’t like the way they feel, or they don’t look cool, life jackets are there for a purpose. Make sure all kids wear their life jackets. A life jacket could easily save your child’s life. Besides – It’s the Law.

- Just like driving a car – Drinking and driving do NOT mix: Have a designated driver if you plan to drink. In Wisconsin boating violations, like drunk driving, count against your driver’s license and your insurance premiums.

- Check Your Lights: Are all of your boat’s lights working correctly? Don’t forget how quickly the sun sets. You don’t want to go back in the dark.

- Watch the Weather: Summer weather in Wisconsin can be unpredictable. Make sure you check the forecast and continue to keep tabs on the weather throughout the day. Don’t get caught in a sudden storm. It only takes about 15 minutes to go from clouds to a violent storm on the Bay.

Avoiding Boating Accidents

Here’s a hard fact: Boating accidents, like failure to yield right of way, to approaching a dock too fast, are all too common. Most of these accidents were avoidable.

Maybe I should have turned wider

Additionally, 15% of all boating deaths had alcohol involved. Another 83% of drowning victims did not have a PFD.

It’s not a question IF boating accidents are a problem but instead, what can be done to reduce the rate of these accidents?

How You Can Prevent a Boating Accident

- Boating and Booze Do Not Mix: Do not drink and operate your vessel. If you take drinking and driving your car seriously, then the same caution should be exercised on the water.

Boat Safety Rule #3- Don’t get a visit from him

Operating a boat while over the alcohol limit is illegal and puts everyone on the water at risk. You have slowed reaction times and a lack of judgment.

- Make PFDs mandatory: So often, an otherwise minimal accident can turn tragic if a passenger falls into the water without it. Remember, they do not have a seatbelt.

Though you may be a good swimmer, there are many ways that you could end up injured and unable to swim. That’s not to mention the possibility of rough waves, which could make swimming back to your boat impossible.

- Follow posted speed and wake limits and stay vigilant for risks.

Like car accidents, some things are out of your control. However, boating accidents are minimized if boaters simply:

- Stay sober behind the wheel,

- Wear PFDs,

- Follow speed and wake limits, and

- Brush up on the essential safety standards of operation.

Is a Boat Safety Course for you?

If you’re a new boater, boating safety courses are a no-brainer. Here are some take-homes you will learn:

- Boat Operation: There are some easily overlooked best practices that can help you avoid collisions, run aground or otherwise damage your boat.

- Emergency Procedures: From fires to dangerous weather, when you’re facing an emergency on the water, every second counts.

- Navigation: Even if you know your favorite boating spot like the back of your hand, there are too many variables to go without trip planning and preparation. These classes can teach you the safest ways to plan your next boating trip.

- Equipment: Even the safest boaters should know what equipment could save their lives in emergency situations. Ensure that all of your safety equipment is up to the task of keeping you and yours out of danger.

- Emergency Cut-Off Switch: If you go overboard, the last thing you want to see is your boat speeding away from you – especially if you aren’t wearing your PFD. Use a kill switch/emergency or cut-off switch fastened to your clothing. This ensures that the engine will shut off if you find yourself thrown into the water. It’s much like the shutoff switch on a treadmill at the gym.

- Keep Contact: Keep others informed about your boating plans. Let them know where you are going, especially if boating alone. Always keep a VHF radio on you, as well as your cell phone, safely stored in a waterproof container.

Boating safety classes will teach you the right procedure for most critical situations you may encounter while boating.

Practice boat safety and enjoy the ride.

Reminder

PWS is located in the center of Door County at 7325 St Hwy 57. It is located 1 mile North of County MM (Hwy 42) and South of Sturgeon Bay. Look for the intersection of Idlewild Road.

Want us to address a dock or boat lift topic for you? Feel free to give us a call.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Jul 17, 2018

Nothing lasts forever – including boat lift cables

Boat Lift cable problems require a thorough explanation.

There are two types of normal cable wear:

- Internal cable abrasion- This occurs whenever strands work against each other under load.

- External abrasion – This will occur when the cable bends around the winch drum and rubs against the adjoining cable wrap. It also occurs when the cable rubs against the side of the winch drum

Frayed Boat Lift Cable

Types of Steel used as a Boat Lift Cable

Galvanized Steel: Galvanized steel is carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. A “hot dip” in a molten zinc bath results in galvanizing the cable. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is stronger than stainless steel. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium forms a chromium oxide layer that promotes resistance to corrosion. When exposed to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium merely needs oxygen to maintain this property of resistance.

All Lift Cables Will Require some Maintenance

The winch and lift cables require periodic attention. Remember, these (2) items do all the “work” on your lift. They do the lifting of the rack assembly with the weight of the entire boat and motor on it.

Boat lift cables are manufactured out of either stainless or galvanized steel.

Galvanized cable is used as the winch cable on heavy boats. Stainless steel cables are used for the remaining cables on top brands like ShoreMaster.

Both types of steel offer the benefit of corrosion resistance and strength. However, watch for the noteworthy differences mentioned above that require your attention.

Corrosion

Galvanized cables that break usually show signs of corrosion or rust in advance. Typically, the failure is located near the winch when the rack is in a lowered position. Another common site for corrosion is at the bottom of the cable where it secures to the frame on some brands.

Rusted Boat Lift Cable

A slight discoloration indicates that the protective galvanizing coating may have worn away. Heavy concentrations of rust indicate that the steel cable is losing strength and requires replacement immediately.

How long should a cable last?

Experts claim galvanized cables require replacement every two years. All things being equal, a stainless cable will last up to twice as long.

A point often overlooked – internal abrasion or rust is hidden and may not show external damage on the cable during a visual inspection. A boat lift cable like this may sometimes fail without prior warning.

Other causes of cable failure

An improperly positioned boat puts extra strain on any boat lift cable. Wave action pounding against the boat hull or jamming the rack against the frame may send your boat into the water with a corroded or damaged cable. Even a new cable may “snap” if you jam the rack against the frame.

When in doubt, replace the cable; trying to squeeze another year out of a $95 cable that you know s damaged or rusting isn’t worth the risk.

In Conclusion… What Can You Do For Your Boat Lift Cable?

- In spring and fall put a short blast or two of PENETRATING OIL on the cables. Spray the cables wrapped around the winch drum from the top of the winch. Do not soak the cable; you’ll only contaminate the water. Use only penetrating oil. A quick spray during the summer is very helpful.

- NEVER USE GREASE to lubricate the cables. (grease traps the moisture inside the cable accelerating its deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed.

- Check all cables to assure correct alignment on the rack pulleys.

- With your boat correctly positioned on the lift, check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack all the way down. Maintain weight on the rack to assure proper tension on the cables.

We hope that this article will make your life easier and lend more confidence to your selections. Your boat lift is an investment, and as such we want to help you make wise decisions.

Reminder

PWS is located in the center of Door County at 7325 St Hwy 57. It is located 1 mile North of County MM (Hwy 42) and South of Sturgeon Bay. Look for the intersection of Idlewild Road.

Want us to address a dock or boat lift topic for you? Feel free to give us a call.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.