When Should a Lift Cable Be Replaced? PART 1 of 2 – UPDATED

When does a Lift Cable need Replacement?

Lift Cable replacement depends on a variety of conditions:

- Was the lift adequately sized for the boat?

- Did you change boats since you originally bought the lift?

- Is there visual damage to the cable?

- How well is the lift cable maintained?

- How often has it been lubricated?

- What lubricant is used?

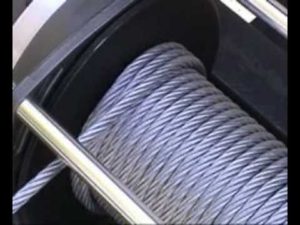

- Is the cable winding correctly on the winch drum?

- Are the cables frayed?

- Is there corrosion on the cable?

When & How Do I Inspect a Lift Cable?

The best time to inspect the cables is when it is on dry land. That way you can check all of the critical points. Ideally, the lifting rack is in the lowered position, so more cable is exposed at the winch. Try not to let the cables go slack by lowering the rack too far.

If you inspect the lift while it’s in the water, raise the lift rack out of the water to do the inspection. A complete inspection at the bottom of the lift cable should be done when the lift is on the shore again.

In both cases, examine all exposed cables for frayed or rusted wires. Pay particular attention to the cable coming from the winch.

What does a frayed boat lift cable look like?

Look for frayed or rusted areas on the cable. The greater the number of frayed wires the greater the risk of failure.

Excessive rust on the cable means there could be major rust inside. Rust indicates a major weakening of the cable

and should be monitored carefully.

CAUTION – Always wear leather gloves when sliding your hands on these cables. The leather will protect your hands from a frayed wire which can be a painful experience for unprotected hands. Cloth gloves will not protect you.

The Next Thing to Inspect

What type of pulley material is used on the lift rack? To cut costs, some manufacturers still use a hard, black plastic pulley. These require extra attention. DO NOT lubricate any of these pulleys. Doing so will only contaminate the water.

If you have the black plastic pulleys (or any plastic pulley for that matter) follow these instructions:

With the rack above the water look inside the exposed ends of the rack tubes:

- Are the sides of the pulleys broken or bent over? (Common with plastic pullies)

- Are the cables still riding on the pulleys?

To completely check the pulleys, you should have someone raise the rack so you can see the entire pulley as it turns. The pulley sides could be damaged, and you can only see a portion of it from the ends of the tubes. Do this at all four corners.

DO NOT place your fingers inside the tube to inspect it when it is moving. You may lose your finger.

Why are Plastic Pulleys inferior?

A lift cable will easily slip off a cracked or broken plastic pulley. With the lift cable off the pulley, the load on the cable is more than double the usual tension. It also results in broken internal wire strands due to the reduced diameter of the new bearing surface.

In this situation, the pulley needs to be replaced immediately. The heavier the boat, the more important this is.

FYI in the case of the brass pulleys used on a ShoreMaster lift, we have never seen a broken or chipped pulley. Note: Only the original vertical jet ski lifts from ShoreMaster had plastic pulleys. ShoreMaster corrected this problem almost immediately and only use brass pulleys on all their lifts today.

One Final Thing to Look For

If you have a sandy beach, look for sand inside the tubes. If sand is built up inside the rack tubes, remove it as soon as possible by flushing the tube out. A sand packed tube can happen after a storm when:

- The water was heavily agitated on a sandy beach; and

- While the rack is in a lowered position.

Sand can pack so tight in the tube that the cable can not move through it. The same is true of seaweed that gets into the tubes.

In Part 2 of this 2 part series, we discuss the types of cables used on lifts today. We will also address the life expectancy of cables.

SEE also – When Should a Lift Cable Be Replaced? PART 2 of 2 – UPDATED

Reminder

PWS is located in the center of Door County at 7325 St Hwy 57. It is located 1 mile North of County MM (Hwy 42) and South of Sturgeon Bay. Look for the intersection of Idlewild Road.

Want us to address a dock or boat lift topic for you? Feel free to give us a call.