Leveling Legs for Boat LIfts (Adjustable) – Pier & Waterfront Solutions

Boat Lift Adjustable Leveling legs – What you Really need to know

Written by Shoremaster marketing Updated by Pier & Waterfront Solutions LLC

Adjustable boat lift leveling legs – You may not need them.

That’s right – You may not need adjustable boat lift legs. Unless your water depth continuously fluctuates throughout the boating season you may not need leveling legs for your boat lift. Wouldn’t it be a shame to pay for that feature when it isn’t needed?

Some boat lift manufacturers automatically incorporate adjustable leveling legs into their boat lift design. This forces customers to pay for them, even when they don’t have a need for them. Why?

It’s their attempt at differentiating their design from the simplicity of a ShoreMaster Boat Lift.

Remember – Simple is always better.

By incorporating adjustable leveling legs in the design, they are also adding to the owners’ maintenance burden. All that for an accessory that may not be required or even wanted by the consumer.

Still feel it is a desirable accessory?

For those that feel it is a desirable accessory, ShoreMaster does offer add-on adjustable leveling legs for boat lifts. However, ShoreMaster boat lift customers aren’t initially required to pay for or maintain an accessory that they may not need.

You may not need them as much as you think you will.

Even if you experience moderate water depth fluctuations, you will likely find that you don’t need adjustable leveling legs.

Here’s an example: even if you experience a drop in a water depth of 12 to 18” over the summer, you may be able to adjust for this. Changing where you position your rack beam may solve the problem for you.

In other words – Your your starting water depth is near 4’. You will likely be able to overcome an in-season water drop of about 12”. Just lower your boat lifts rack an additional 12” to allow access to your boat lift. If you have a shallow lake, you may have the lift positioned with the rack as low as it goes right from the start. No further adjustment is allowed.

What good will the lift leg system do if you can’t go any further down? It’s that simple. There may be no need, or ability, to adjust the overall height of your boat lift at all.

In reality, you usually will not need to adjust your lift legs after your initial install. Why pay for something that requires more maintenance over the years?

ShoreMaster’s adjustable leveling legs are an add-on feature for new or existing boat lifts. That’s a win for current and future boat lift customers.

Adjustable boat lift legs are not as adjustable as you might think.

Adjustable Leveling Legs do provide a convenience that works well for an only a few boat lift owners

It is important to make sure that the amount of vertical travel is adequate for their water fluctuation. After all, built in lift leveling legs will do you no good if they don’t provide an adequate amount of travel.

The Case for All Add-On Boat Lift Accessories

It’s pretty difficult to improve on the time-tested design of a ShoreMaster vertical DVS boat lift. That’s because a boat lift’s design should be:

- simple,

- durable, and

- should not require constant maintenance or tightening of bolts.

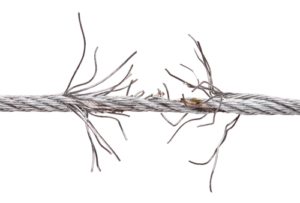

Shoremasters welded frame design and simple pulley system, making it extremely simple and durable. Normal maintenance usually consists of replacing a cable every few years as needed.

ShoreMaster has a record for years of dependable service with minimal maintenance.

When you incorporate adjustable leveling legs into the design of a boat lift, you reduce the simplicity of the lift and increase the maintenance requirements.

Along with this reduction in boat lift simplicity comes:

- increased potential for problems,

- more need for maintenance,

- added weight; and

- higher cost.

Unless the innovation is something that benefits all customers, you are forcing them to pay for things they will never use. With ShoreMaster’s Adjustable Boat Lift Screw Legs as an add-on feature, you can always put a leg leveling system on if you need it

You’re not wasting your time and money maintaining an accessory that you didn’t require in the first place.

Reminder

Pier & Waterfront Solutions specializes in ShoreMaster docks, lifts, and accessories – both residential and commercial. We service the rest.

PWS is located in the center of Door County at 7325 St Hwy 57. Located 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the intersection of Idlewild Road, our staff is ready to serve your needs.

If you have a dock or boat lift topic or issue you would like to see addressed on our site, feel free to give us a call. We believe that an informed consumer makes better decisions.