WIRE ROPE LUBRICATION

Wire Rope Lubricants

Wire rope lubrication is critical to extending the life of a cable (often referred to as the “lift cable”). How significant is it? Failure to complete this simple maintenance can reduce wire rope life by up to 50%.

Tell me more!

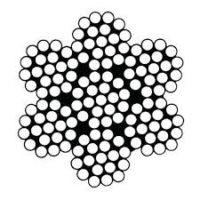

A wire rope consists of wire strands wound around a central core, then again wound around themselves to form a wire rope. The center may consist of steel or even plastics. Here are just some of the MANY different configurations for a wire rope.

The use of a small strand size is better suited to bending around small sheaves (pulleys). Taken to an extreme, a wire made of one thick “strand” would not be able to go around a pulley.

Many small strands allow the wire rope to bend easily around the pulleys. In doing so, the strands “rub” against each other, causing friction. Over time, friction rubs any external coatings off the wire rope.

How are the wire rope strands protected against rust?

Uncoated wire rope strands left “uncoated” will rust from exposure to moisture in the air;

The cable strands get a coating of zinc for rust protection (called galvanizing). The steel strands travel through a hot zinc bath to coat the surface with rust protection. The “con” to galvanized cables – the surface does not regenerate when damaged.

What about stainless steel cables?

In simplest terms, when molten high carbon steel mixes with chromium, it forms stainless steel. When in contact with air, the chrome restores the anti-rust properties. The “con” side – it gives up small amounts of strength.

What function does lubricating a wire rope perform?

Wire rope lubricants;

1. Reduce friction in the layers of the wire rope as they move over other layers. It’s true for galvanized & stainless steel cables both; and

2. Lubricants provide corrosion protection and lubrication in the core of the cable. Less rust and friction means longer life for the cables.

Are there different lubricants used?

There are different types of wire rope lubricants – penetrating and coating. Solvents in penetrating oils carry a lubricant into the core of the wire rope. When the solvent evaporates, it leaves behind a lubricating film to protect the strands.

“Coating” lubricants (grease) barely penetrate a cable. The coating seals the outside of the cable from moisture and reduces wear and corrosion. But, it also seals moisture inside the cable, thus promoting the rusting process.

PWS recommends only penetrating lubricants.

Most wire ropes fail on the inside first. It is vital to ensure that the center core receives enough lubrication. Repeated applications over a day are a good idea.

It is best to apply short bursts of spray lubricant on the top cables wound around the drum. Spray across the top of the wires to get the best penetration and protection. The rope strands tend to separate slightly due to bending around the winch drum. This separation allows the lubricant better access to the core of the wire rope.

Four Rules to follow:

- Do not apply a grease lubricant on a boat lift cable;

- Never change the diameter of the lift cable;

- Never substitute a different wire construction; and

- Do not replace stainless steel cables with galvanized cables.

Experience suggests that life cycles may double with lubrication. But remember, there are other factors affecting wire rope life also.

PWS attributes the increase in the life cycle to the use of penetrating oil to displace water and decrease friction. The oil reduces the wear and corrosion occurring inside the rope. Spraying with a penetrating lubricant acts like an oil change for cars. You’d never allow your vehicle to run out of oil. Right?

The savings from lubrication versus replacing a lift cable are considerable.

What else can damage a boat lift cable?

Improper winding and shock loading with heavy loads damage the cables. These actions will speed up wear and corrosion. See this link.

WHAT ABOUT MY BOAT LIFT?

In a previous post, we explained the danger to boat lift cables if the waves hit the bottom of your boat. We also demonstrated what defective wires look.

7 x 7 cable construction

Once again, here are the warning signs of defects in your cables.

If your cable looks like any of these, it’s time to replace them.

Warning – It is possible to break strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust. If you see “rust” on a stainless steel cable, it is from the winch drum depositing rust in the winding process.

Visit Pier & Waterfront Solutions on Facebook also.

Tell Your Friends & Family

Have friends or neighbors you believe would like to see this article? Email them this link – they’ll thank you!

Where is PWS?

You will find us at the intersection of Idlewild Road and Hwy 57 in Door County. The address is 7325 St. Hwy 57, Sturgeon Bay. That’s 3 miles south of Sturgeon Bay, and 1 mile north of the intersection with Cty MM.

Our staff looks forward to serving ALL your waterfront needs.

Contact:

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – erosion control and shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – commercial work and new & used Sales.

John @ (920) 493- 4405 or John@wisconsinpws.com – Scheduling & Service work.