USED BOAT LIFT GUIDE – Part 2

Are you thinking about buying a used boat lift? This two-part series concludes with four additional items to check. Upon completion, we will have guided you through eight problems to look for when buying a used boat lift.

See Part 1 for the first four checks.

Here’s the second list of things to check:

- Does the cable wind smoothly and correctly on the winch?

- Do the cables have rust on them? Does it use galvanized or stainless steel cables?

- Are there any “kinks” or other visible problems on the cable?

- How often were they lubricated, and with what lubricant?

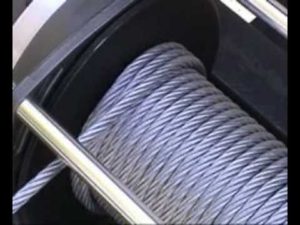

Does the cable wind smoothly around the winch?

If you look up inside the winch housing, if it has an enclosure, you will be able to see how the cables are winding. It should be a smooth pattern without any “crossed” cables. If the winch has no outer covering, you can readily see the pattern.

The wire cable has a “memory” to it. Once the cable gets crossed, it will tend to do it again the next time the cable rewinds.

If the cable is wrapping in layers, you will get a thunderous sound when the cable finally “falls off” the stack. This movement scrapes the galvanizing of the wire, and rust will form. The “shock” of dropping a 2,000# (or more) weight will also apply excessive stress on the cables.

Do the cables have rust on them?

Galvanized cables will rust over time. The movement of individual strands of the wire against each other cause rust. This movement occurs as they wrap around the winch and pulleys. There is no way to end this.

The only thing you can do is lubricate the cables. The lubrication reduces the friction between individual strands. Lubrication, in turn, lengthens the life of the cable. For more details click HERE.

Rust on the cable indicates that some galvanizing has worn off. Individual wire strands are compromised.

What about rust on a stainless steel cable?

Stainless steel does not rust, but it does pick up loose rust from the winch. Winches are plain steel with a painted surface. When the paint rubs off, the steel will rust and “bleed” onto the cable.

It’s much like a scratch on a car. The rust will run down the side of the vehicle.

The rust typically appears near the winch when the rack is in a lowered position. Under these circumstances, it’s ok. Try to lubricate the cables every year to slow this down.

Are there any visible signs of problems with the cables?

We recommend you lower the “rack” down, but DO NOT allow “slack” to form in the cables. Slack in the cables will allow the windings at the winch to unwind and cross over each other.

It’s much like a fishing reel getting snagged when there is no tension on the line.

Are the cables on the used boat lift adjusted equally?

If three of the four corner cables appear “tight,” the cables will need re-adjustment to re-distribute the weight equally.

Even proper positioning of the boat is essential.

If it takes excessive weight to lower the rack, look at the pulleys in each corner. Are they free to move? Is there sand, seaweed, or reeds packed around the pulleys? Remove any debris to free up the rack.

If any pulleys resist rotation, the rack will not lower smoothly. You must find out why the rack is not moving.

Note: In the case of jet ski lifts, the weight of the rack may not be enough to cause the rack to lower by itself. Have someone lean of the back of the lift to assist the rack in lowering. Still, hanging up? Check all the pulleys as above.

Check the fittings on the ends of the cable. Has rust formed on the fittings, or are there broken strands?

Caution– watch out for the ends of the cables. It’s a painful reminder of exposed strands.

Examine the entire length of the cable for frays (broken strands).

Caution – DO NOT run your hand up and down the cable without leather gloves. Broken strands on the cable will cause painful cuts on an unprotected hand. Ordinary cloth gloves will not protect your hand.

Are there any “kinks” or other visible problems?

Here are the warning signs of defects in your cables.

If your cable looks like any of these, it’s time to replace them.

Warning – it is possible to have broken strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

Read this article to learn how to lubricate cables. Lubrication slows down premature corrosion. It’s simple and easy to do.

What is the proper lift cable maintenance?

Cable replacement requires a visual inspection of the lift cables. It’s best to inspect it while it is on dry land to check the critical points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Examine the vertical length of the cable for frayed wires, especially near the winch. Excessive fraying or corrosion near the winch is a top signal of damage.

CAUTION – Always wear leather gloves when sliding your hands along the cable. A frayed wire can cause painful damage to unprotected hands.

There are two types of cable wear:

- Internal cable abrasion- Occurs whenever strands work against each other under load.

- External abrasion – Occurs when the cable bends around the winch drum or against the side of the drum.

Every time the boat is raised or lowered, there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When the strands break, they lose strength.

Assuming the cable is well cared for, how long should it last?

Experts say that to be safe- replace a galvanized cable every two years. All things being equal, the stainless cable will last longer. Up to 2X as long.

A point often overlooked – internal abrasion and rust are hidden, and there may be no visible damage. A boat lift cable like this will fail without prior warning.

When in doubt, plan on replacing the cables. Trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

PWS handles Shoremaster cables and can provide new cables for all brands.

Nothing lasts forever – even boat lift cables.

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

John @ (920) 493-4405 or John@wisconsinpws.com – Scheduling & Service work