Nov 7, 2017

Remove the Jet Ski Lift from the water

Jet ski lifts need to be removed from the water for the winter in Northern climates to prevent major damage.

Dock-mounted lifts that rotate over the dock should be stored over the dock and secured in case of storms. The Jet ski itself should NEVER be stored on the lift for the winter. Ice accumulations can severely damage the lift. Non-rotating or free standing lifts need to be removed from the water

Jet Ski Lifts- simple yearly Maintenance

Jet ski lifts require simple winterizing maintenance at the end of the boating season in order to prolong it’s life.

ShoreMaster Cantilever Jet Ski Lift

Here are some things you should do:

- Inspect the jet ski lift at the end of the season for worn parts, frayed cables (extremely important), loose bolts, etc

- For electric powered jet ski lifts, remove the motor and store it inside of a building or relieve the tension on the bungee cords, if so equipped.

- If the water will be freezing during the winter, move the lift to dry land

- Check bearings for noise and proper operation

- Make sure there is no vegetation or sand in the rack frames

- Check all pulleys and other wearable parts for damage. On older models, with plastic pulleys, rotate the pulleys by hand to insure none of the pulley edges are broken. In general, these must be replaced.

- Ensure that the lift moves freely up & down without binding or straining. A general rule when lowering the rack is to maintain downward pressure on the rack.

- For electric jet ski lifts, remove the motor and store it out of the weather or, at a minimum, relieve the tension on the bungee cords, if so equipped.

- All cables should have a quick spray of penetrating oil applied to them, including on the cable wrapped around the winch drum. However, DO NOT APPLY any oil inside the winch mechanism itself.

- Is it time to replace the carpet on the lift bunks or should you consider replacing them with maintenance-free vinyl bunks?

When should I consider these adjustments

Fall or early Spring is a good time to order replacement parts for your jet ski lift. Call or email Pier & Waterfront Solutions for replacement parts. When spring arrives the lift manufacturers have very busy shipping schedules and parts can take longer to get.

Be ready for summer fun.

Enjoy the summer on your jet ski

Sep 12, 2017

Boat Lift Cables Require Maintenance

Boat Lift cables, along with the winch on your lift, are the (2) most important components of a boat lift. As a result, they require periodic attention. Remember, these (2) pieces do all the “work” on your lift. They do the lifting by raising the rack assembly with the weight of the watercraft on it. Lift cables allow your boat, pontoon or PWC to be raised and lowered when you need them.

The lift cables are made of either stainless or galvanized steel.

Both types of steel offer the benefit of corrosion resistance and strength. But there are some noteworthy differences that you need to pay attention to if you are deciding on a new or used lift or just plain replacing the cables.

You need to look at the available options and be able to do simple maintenance on either type of cable. With your owner’s manual, the correct part number, weight capacity, and type of cable should be listed. If it is not listed, or you do not have an owner’s manual, you can contact PWS to get assistance in determining what cables your lift requires regardless of the brand. PWS can get the correct cables so the cables can be replaced correctly.

Types of Steel used as Boat Lift Cables

Galvanized Steel: Galvanized steel is a carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. This is accomplished through a “hot dip” in a zinc bath. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is strong and each cable is made to handle the loads created by your boat lift. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium in the steel forms a thin layer of chromium oxide that promotes resistance to corrosion. When exposes to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium simply oxygen to maintain this property of resistance.

Getting technical now

Galvanized steel boat lift cables, although corrosion resistant, are more prone to wear. The zinc layer can be scratched or cracked through expansion and contraction. This can lead to spot rusting and a decreased life of the steel cable. The scratching occurs when a cable rubs against itself as it winds around the winch drum. Each layer is going at a slightly different speed than the layer below it – thus scratching the zinc coating on the cable.

Even internally the strands in the cable are rotating at a different speed and the zinc will be damaged. This can be frequently seen on the upper areas of a galvanized cable where it enters the winch. It also frequently occurs on the bottom layer of a cable where it is wrapped around the drum on the winch.

Stainless steel boat lift cables, on the other hand, are blended with chromium oxide during manufacturing. This makes its corrosion resistance regenerative in fresh water.

Rusted Boat Lift Cables

You will see lift cable corrosion most commonly in the form of rust.

Galvanized steel cables will corrode over larger areas of its surface while stainless steel cables seldom rust. The addition of chromium to the steel during the production process creates a product that is regenerative and uniform in resistance throughout.

Whereas galvanized steel, with its zinc coating, does not regenerate and when damaged exposes the steel beneath to the elements. The rusted areas are more prone to fraying and breakage too.

In Conclusion … Follow these Maintenance Suggestions for your Boat Lift:

- In spring and fall (and at least once during the summer months), put a short blast or two of PENETRATING OIL on the cables wrapped around the winch drum from the top of the winch. Do not soak the cable, you’ll contaminate the water below. DO NOT use any oil except penetrating oil. NEVER USE GREASE (it traps the moisture inside the cable accelerating it’s deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed, if corrosion is present.

- Check all cables to make sure they’re aligned properly on the pulleys

- With your watercraft on the rack – check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack fully down (but without slack in the lifting cables.)

- If the canopy cover is on, are all the springs or bungee cords secured? Broken hardware should be immediately replaced.

- Check bunks and guides to make sure the hardware is secure.

- If carpeted, replace torn bunk and guide fabrics to protect your boat hull. Consider replacing carpet with vinyl bunks.

- Exterior wheel driven winch? Check the bungee cord to see if it needs replacement. Cracked cords can break at any time so be sure to use the correct cord. Contact PWS for replacements.

- Don’t ignore your dock – check the bolts. Are they secure ?

It is our hope that this article will make your decision easier and lend more confidence to your selection. Your boat lift is an investment and as such we want to make certain that we help you make a wise decision.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 23, 2017

Excerpts from Cabela’s NWT 2017 8/8/17 edition

A National Walleye Tour event is one thing. The National Championship event is quite another thing for Marinette The Cabela’s National Walleye Tour held its championship event at the newly developed Menekaunee Harbor Marina in Marinette, WI, Aug 16-18.

The Marina was rebuilt by Pier & Waterfront Solutions just in time for its christening by the NWT event.

About 100 two person teams participated in the walleye tournament to christen the redesigned Menekaunee Harbor facilities.

The boat launch and marina facilities were completed late this summer just in time to greet the walleye tournament. It was great way to expose the new marina facilities to the public.

Marinette now has a “class act” with their new facilities.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster accessories for docks and lifts. Located in the center of Door County at 7325 State Hwy 57 south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

See our Facebook page – (Pier and Waterfront Solutions) – for photos of our 2016 & 2017 seasons including residential and commercial applications.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

. Coming Soon – “The PWS Store” on our website.

Aug 15, 2017

Replacement Boat Lift Canopies require proper dimensions

Time to replace your old canopy? By now you know that PWS can provide replacement parts for almost all dock and boat lift brands. Did you know PWS also provides replacement boat lift canopies for most brands on the market?

Here’s a complete list of boat lift canopies available:

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- Beach King

- Daka

- DockRight

- Floe

- Harbormaster

- Hewitt

- LakeShore

- Newman’s

- Vibo

- Pier Pleasure

- Porta-Dock

- ShoreMaster

- Shorestation

Love your boat? Then you want to give it a good home. This is why many boat owners choose Shoremaster Boat Lift Canopies to protect their boats. Known for the quality and longevity of their products, Shoremaster Boat Lift canopies are made to last for years and years, giving your boat the protection it deserves.

Because of the quality workmanship of a Shoremaster canopy frame, you will most likely need to replace your Shoremaster canopies fabric long before the frame itself begins to deteriorate.

In the Door County peninsula, one of the most popular boat lifts is a ShoreMaster lift.

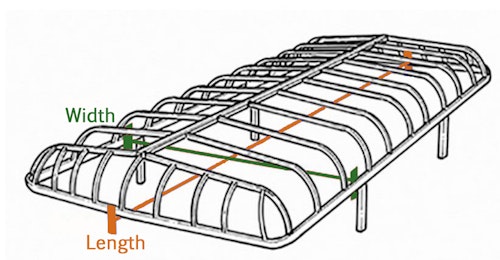

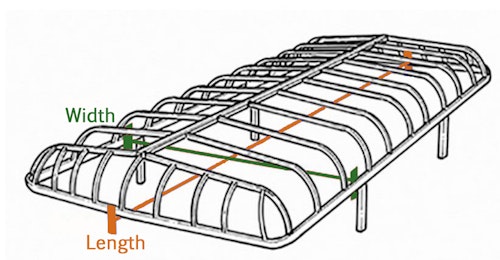

Measuring for ShoreMaster replacement Canopies

Here is the correct way to measure for a replacement canopy for these lifts:

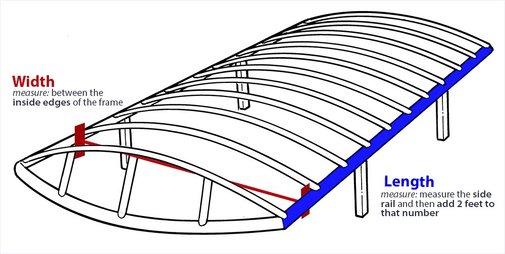

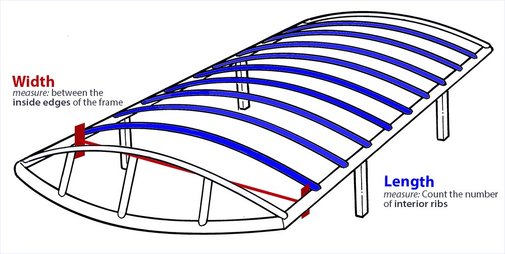

Refer to the diagram below for more information on measurements.

Length: Measure from the frame’s outside edge to outside edge, along with the center line (not up and over the top)

Width: Measure between the inside edges of the frame.

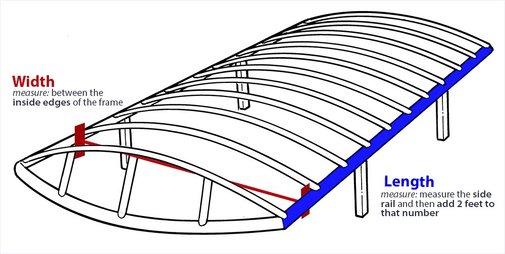

How to measure a Shorestation canopy:

Shorestation lifts are made with Steel or Aluminum canopy frames. It’s important to distinguish between the two before proceeding:

Shorestation ALUMINUM Canopy Frames

Note: References to Steel or Aluminum refers to the canopy frame materials only.

Measuring and Sizes

Length: Measure the side rail and then add 2 feet to that number

Width: Measure between the inside edges of the frame

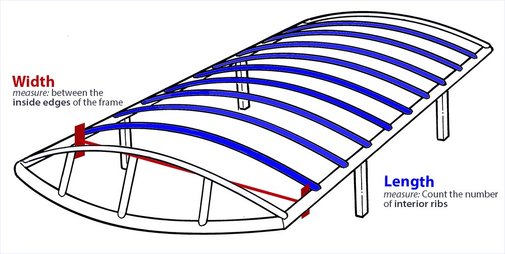

Shorestation STEEL Canopy Frames

Note: References to Steel or Aluminum refers to the canopy frame materials only.

Measuring and Sizes

Length: Count the number of inner ribs

Width: Measure between the inside edges of the frame

PLEASE NOTE: If you feel there have been ANY modifications to the canopy frame in the past it is very important to bring that information to our attention. These changes may have a direct result on the final product.

Another option is to have a PWS representative visit your site and get the proper information for you.

Not either brand?

Look for the brand name on the frame or winch of the boat lift and call or send the information to us. Sending a photo helps also. Based on the information you send, we will return a diagram of the frames to you to compare with your actual canopy frame. We will also show you how to take the precise canopy dimensions we need. It’s as simple as that!

If in doubt just ask us to send someone out to get the information we need.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster accessories for docks and lifts. We are located in the center of the Door County Peninsula at 7325 St. Hwy 42/57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Located in the center of Door County at 7325 State Hwy 57 south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

See our Facebook page – (Pier and Waterfront Solutions) – for photos of our 2016 & 2017 seasons including residential and commercial applications.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 8, 2017

Dock Bumpers Protect your Investment

Dock bumpers protect your boat and dock from damage. You have a major investment in your boat and dock system. Dock bumpers go a long way to protect that investment. The bumpers come in several styles. The selection of the correct one for you is basically determined by your location.

Rivers and Lakes

Docks installed less than 18″ above the water level will allow the use of horizontal side bumpers. These bumpers will work for you, unless you experience waves over 18″ or have large water depth fluctuations. Horizontal side bumpers are available in several configurations.

Horizontal Side Bumpers

Dock Side Bumper

A side bumper wraps over the top and/or upper part of the dock frame. and are made in 10′ lengths. The sections are cut to accommodate posts and accessories. The side bumper may be cut to conform to the size of the deck panels for ease of winter removal. The bumper protects the hull of the boat from hitting the top and side of the dock. Normally, it is not applied to the bottom of the dock frame..

Corner Bumpers

Dock Corner Bumper

The corner bumpers are made from the same material as the side bumpers. It is factory formed into a right angle to protect the boat hull from two directions at the corner of a dock. Mounted at the end of the dock, they measure approximately 12” in each direction.

Dock Corner Wheel

An alternative is a vinyl wheel which mounts at a corner. This wheel rolls horizontally around the corner to guide and protect the boat hull.

The wheel does take up about 6″-*8″ of deck space in the corner. It will not be effective if you have large waves. You may be under or over the wheel and need a bumper that allows the boat to go up and down.

Large Lakes and the Bay of Green Bay

Vertical Bumpers must be used on larger bodies of water like the Bay of Green Bay and Lake Winnebago. They experience water fluctuations larger than 12″ and wave action exceeding three feet. This is particularly important when the dock is set high to accommodate wave action. This type of bumper will help prevent you boat from going under the dock frame.

Vertical Dock Bumper

Docks set over 24” above the water have a unique problem. If the side of the boat moves under the frame of the dock it will cause severe damage to the boat. A horizontal side bumper can not prevent this type of damage.

3′ high vertical dock bumpers prevent the boat from moving under the dock frame when in the trough of a wave.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts and accessories.

Located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection of Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Found this article helpful? Go to “NEWS” on any page of our website for a complete list of articles meant to keep you informed on the latest product information and maintenance issues. Check out our “older entries” also.

The wide variety of articles on dock and boat lifts issues will answer many of your questions. PWS believes that an informed consumer makes better decisions.

Check out our Facebook page at “Pier & Waterfront Solutions.”

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Coming Soon – “The PWS Store” on our website