Mar 5, 2019

Power Options for Boat Lift Motors

Boat lift Motors are covered in this 2 part series. We discuss the different types of operating systems for boat lift motors. Installing a boat lift motor makes your life so much easier. If you can operate a garage door opener, you can run a boat lift motor.

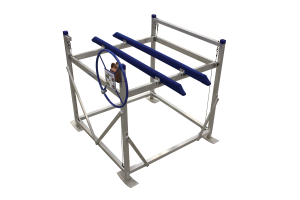

Lift Boss

You have three choices to consider for powering a boat lift motor.

- An A.C. operated system;

- A 12V system; Or

- A 24V system.

PWS does not usually recommend an A.C. powered system. Why? It usually means running an extension cord to the motor. Your safety and the safety of the people near you are our primary concern.

Using an A.C. operated lift motor means the extension cord(s) and the connections will be exposed to the elements. These include – Rain, morning dew, splashing from waves, and the list goes on. As a result, there is a potential to expose people to ESD. For a further explanation read this article.

You could be endangering children (or grandchildren) and even your neighbors to electrical shocks. ESD can be deadly and not only threatens swimmers but the people who attempt to rescue them.

Beside safety reasons what other dangers are there?

First, some background info. The smaller the Gauge (Ga.) size, the heavier the wire is. Thus, a 12 gauge wire has a “heavier” wire than an 18 Ga. Typical household extension cords – those brown or white cords – are 18 – 20 Guage (Ga). The wiring in your house is a 14 Ga. 12 Ga. is used in kitchens and bathrooms due to higher amperage requirements. A smaller diameter wire will have a higher resistance to current flow. Thus, more heat is generated in the wire and connections. You want the least amount of heat as possible.

What is Voltage Drop?

The electrical source you use usually will be a circuit run underground or along poles to a power box near the water. At this point, you probably are thinking – “So what, I’ll just run an extension cord to the motor.” On the bay of Green Bay and the Door County peninsula, in particular, you may be looking at the need for a 100’-200’ extension cord. This likely means a second extension cord and more voltage drop. This will get the power across the shoreline to the location of the motor. This presents some problems.

In reality, the longer the extension cord is, the more “voltage drop” will occur. Think of it this way – to turn that motor you need a specific voltage (110V) and amperage. If you experience a voltage drop due to the length of the extension cord, it will require more amperage or current flow make up for the loss in voltage to operate that motor. This situation causes wires to heat up and motors to run hotter. An overheated motor will trip the breakers and damage the motor.

If you’re starting at 110 volts and the voltage drops 3%, it won’t matter to a small appliance or light bulb that the voltage is now 117 volts. However, if you plug in a 100-foot extension cord, the voltage will drop about 6 percent to 104 volts. The motor will run hotter.

Motors generally need heavier gauge wires, in this case, 12 Ga. You would not plug a window air conditioner into those “brown” 18-20 Ga. extensions cord you find at the supermarket. Even a short 4 ft cord like that will almost instantly trip a breaker – IF you are lucky. A fire will occur if you are not so fortunate.

Motors and Extension Cords do not mix well.

Voltage drops can cause loss of efficiency, and this will mean a shorter life span for the motor. It is essential to use the right gauge of wire when running wires for a long distance and keep the cords as short as possible with as few connections as possible.

Electrical cord Guidelines

The best practice is don’t use an extension cord if you don’t have to. Since this isn’t always practical, follow these guidelines for using extension cords with motors to minimize voltage drop:

Electrical cord with GFCI device

- Use a GFCIs, or Ground Fault Circuit Interrupters to disconnect power if a potentially dangerous situation occurs. A GFCI interpreter will instantly respond, preventing possible electrocution-related accidents.

- Always use the shortest extension cord possible.

- Use only one cord (there is a voltage drop across the connectors also)

- Use the heaviest Ga. possible – usually a 12 Ga. wire.

- Route extension cords safely and securely. Never place them where they will be damaged or drop into the water.

- If more than one cord is required, use the same on both cords

- Use only extension cords rated for outdoor UV resistance.

- Protect the connectors from the water.

- Do not use damaged cords. Watch out for electrical tape on extension cords.

These are important safety considerations. Choosing the right wire for the job is a critical safety measure.

The best practice is don’t use an extension cord if you don’t have to.

About 50 people die, and 270 people are injured each year when extension cords are strung together.

In part two of this series, we will discuss the two variations for D.C. motors.

Do you have a friend that may be interested in this information? Please share a link to this page with them.

Need Help Selecting a Boat Lift Motor?

PWS is located at 7325 St. Hwy 57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection.

Our staff is here year-round to assist you.

Feb 26, 2019

Boat Lift Calculations

Boat lift calculations are explained in Part 4 of this series.

Have a new boat and don’t know what boat lift size you need? We will outline the general procedure for determining the proper boat lift size to use. Much of the information we ask for can be taken from the boat registration. To give you an accurate estimate we need as much information as possible.

Finding the Overall Weight

Where can the specifications for your boat be found?

The specifications may be provided in a brochure, on a website or a specification sheet. If you can’t find them, among other resources, try using the online NADA guides www.nadaguides.com/Boats/. Go to the website, and look for “specifications” for your model and year.

Before giving you a final recommendation on lift capacities, we usually check more than one source. We always use the higher of the two numbers if there is a difference.

For this post, we went to nadaguides.com/Boats/2013/Chaparral-Boats/H2O-19-SPORT__/32036233. We selected the 2013 Chaparral Boats H2O 19 SPORT.

2013 Chaparral Boats H2O 19 SPORT.

The following (edited) information comes from that website.

Suncoast model weight includes the weight of the outboard motor.

[As you see below, there are (10) different engine sizes available. That means (10) different weights. Thre information is correct if they used the original motor from the manufacturer. It is best to check this information against your actual motor(s).]

115-135 HP (3.0L)

136-200 HP (3.0L – 4.3L) (included)

201-230 HP (4.3L – 5.0L ##)

231-265 HP (5.0L – 5.7L ##)

266-300 HP (5.7L #)

301-350 HP (5.7L – 8.1L ##)

351-400 HP (5.7L – 8.1L ##)

401-425 HP (8.1L ##)

426-470 HP (8.1L ##)

471-500 HP (8.1L ##)

Engine selection Key – (#) For 1993-1997 model years include 7.4L (300 HP) Mercruiser engine.

(##) Use your engine’s horsepower rating.

Under specifications, you will also find: [Condensed for our purposes]

Horsepower (bhp) 135

Length (ft-in / m) 19′ 4” / 5.9

Beam (in / m) 90 / 2.3

Dry Weight (lbs / kg) 2540 / 1152

Fuel Capacity (gal / L) 30 / 114

Please note, the dry weight provided by the manufacturer often does not account for the weight of outboard motors. Be sure you know what the number represents.

If, at any time, you would rather have PWS do the calculations for you, contact us with this information:

Model year;

Brand;

Model; and

Length of your boat.

What other items are needed for boat lift calculations?

You now have the manufacturers’ boat weight. We still need to account for:

- The weight of the fuel;

- All gear on the boat;

- Water storage;

- Non-factory additions.

Keep in mind, you will be lifting all of that weight each time your boat is raised out of the water.

IMPORTANT – EVERY boat lift manufacturer will tell you that lifts are NOT designed to transport people.

In real life, we also realize that the elderly or children often stay in the boat until it is raised. We do NOT recommend this, and you take responsibility for this action.

However, if you must take this action – allow for that added weight in your calculations. Remember, the lift can only handle it’s rated capacity. If you transport people, you are also assuming that the cables are at 100% capacity with no rust or frays. See also – https://wisconsinpws.com/lift-cable-inspection-replacement/

Now let’s look at the information provided above:

Gasoline weighs approximately 6 -7 # per gallon. Multiply this number times the capacity of your fuel tank to arrive at the weight of a full tank of gas.

Water weighs approximately 8 lbs. per gallon. Now check the capacity of all freshwater tanks, wastewater tanks and don’t forget any live wells.

Non-factory modifications – These include wakeboard towers, bimini tops, extra seating, generators, coolers, and swim platforms. It all adds up.

Gear – This include skis, wakeboards, scuba equipment, etc.

Now, add these numbers to your boat weight.

Think you’re done? Not quite yet!

Now add a “margin of safety.” This is usually between 10% and 20%. At this point, we select the next higher capacity for your lift. Why the need for all this? Here’s a simple example of why we do this.

A man picks up a ball. For our purposes, let’s say it weighs ¼ #. This presents no problem.

Next, the same ball is coming towards him at 90 mph. It hits him. It hits him. Do you think the ball “feels like” it weighs only 1/4 #? Obviously, the moving object will have the effect of “more weight’ even though it still weighs just ounces.

Why the comparison? Many times in a storm, the waves will wash against the bottom of a boat. In severe storms, the boat may actually bounce up and down on the lift as the wave rolls across the bottom. Now you have a boat weighing 2,500 – 3,200 pounds bouncing up and down. The added “weight” of the boat at this time may result in a cable breaking. This situation is especially true if the lift was not properly sized originally or the cables are not in good shape. In severe cases, the boat may be washed off the lift completely. A future post will address the insurance issue – watch for it.

Will the lift be able to take the “shock” of that bouncing? That’s why we go to the next size up. This is a common cause of cable failure. These “shocks” could cause a cable to break if they have rust or frayed strands. For more information SEE https://wisconsinpws.com/wp-admin/post.php?post=404&action=edit

The initial extra fee is small in comparison to the cost of damage to the lift or your boat. You could lose your boat & motor completely.

Do I need more Information?

What other things adversely impact a boat lift? What if your boat is in a downpour without a canopy or cover? Did you remove the drain plug while the boat is on the lift? (Don’t forget to replace it before you lower the boat).

What if you don’t know that the bilge pump is malfunctioning. These things may result in lift failure. A safety margin and a few extra dollars now may save you a lot of $$$$ later.

The point is that little things can add up and it is best to err on the side of caution.

What’s next?

The next step is to look at your boat WIDTH. In our example, we have a 90” width.

Does this mean a 96” width lift will work for you? Not even on a calm day!

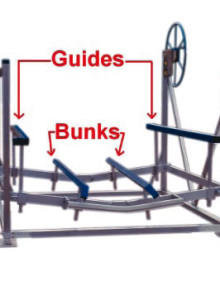

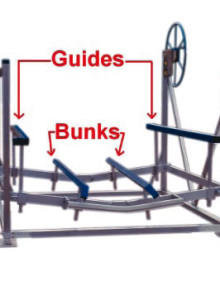

Bunks & Guide options

We equip our boat lifts with guides to keep you centered on the bunks as shown in this example. The guides require a minimum of 6” width each – that’s 12” for a total of 102” in this example. Ok, so a 108” lift will work – right? Wrong!

If you have deep water, you can maintain control of your boat on a calm day. You might be able to get by with a 108” wide lift. However, what if the wind is blowing from the back or one side? Can you control your boat under with only 6” of “spare room”?

In shallow water, you have to “trim” (raise) the motor. Shallow water is the usual situation on the bay of Green Bay. When you trim your motor, you lose control of the direction and speed you are entering the lift. Any decent wave will push you to one side. How many days are absolutely calm?

We are going to cover this situation in more depth in an upcoming post but for now, follow our recommendation for a 120” width. This width will do three things for you:

1. Allow the “guides” to place you properly on the lift;

2. Reduce the risk of damage to your boat and dock; and

3. Give you a higher resale value.

We never have a complaint about the lift being too wide

IS YOUR BOAT CENTERED?

Although not part of the equation – is your boat centered width-wise? Failure to do so will put added strain on the cables on one side. The lift ratings are based on equal weight distribution on all of the cables.

Don’t forget – you need to correctly place your boat “forward” on the lift also. If it is too far forward or back, you have too much weight on the front or rear cables. You risk breaking a cable. The weight has to be distributed equally on the front and rear cables. In a storm, this can also be a factor in your boat being washed off the lift despite being in it’s highest position.

What happens when the boat is too far forward or backward? For more information See https://wisconsinpws.com/wp-admin/post.php?post=1944&action=edit

After all this, you now have the proper lift capacity and the correct width. That about sums it up.

By the way – What would be our recommendation for this example – a ShoreMaster vertical boat lift – SM4010 DVS. (4,000# capacity, 120” wide).

Happy Boating!

Need Help Selecting a Boat Lift For Your Home or Cottage?

Do you have a friend that may be interested in this information? Please share a link to this page with them.

PWS is located at 7325 St. Hwy 57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection.

Our staff is here year-round to assist you.

Feb 19, 2019

WHAT SIZE BOATLIFT DO I NEED?

What size boatlift do you need? Purchasing a new boatlift does not have to be a confusing time. Yet, you have a lot to consider before making your final decision. By spending a little time here, you will be better educated and able to ask the right questions. Ultimately it will ensure you make a better choice.

In addition to getting the numbers, here are some things to consider:

How big is the body of water you will be on?

For instance, will you be on the bay of Green Bay, Lake Winnebago or are you on an inland lake or river? In general, the larger the body of water, the larger the waves will be and the higher your boat must be.

Are there significant fluctuations in water depth during the boating season?

Green Bay and Lake Winnebago present unique situations for boaters because these two bodies of water have substantial variations in water depth and wave action every year. Why are these fluctuations so significant?

When these two situations combine, you want a lift that puts your boat well above the water, so your investment is safe.

How about the boatlift frame construction?

You need a durable frame construction to withstand the boat weight and pressures from the waveWelded side frames prevent any lateral movement in the lift. With age, every time you put your boat on them, bolted side frames move laterally. This will eventually result in enlarged bolt holes, rusted bolts, and loose nuts from the movement of the side frames.

Welded Areas on Side Frames

Compare to other manufacturers

Most brands use bolts everywhere, so shipping is less expensive. The more bolts used in the side frames, the weaker the entire structure is. By comparison, the ShoreMaster boatlift with welded side frames prevents lateral movement.

Only ShoreMaster boatlifts have a welded “V” frame to make access to your boat easier. You do not have to crawl over a horizontal bar to get into your boat.

What is the gauge (material thickness) of the Frame?

The best-constructed boatlifts have aluminum, welded frames using heavy gauge, square or rectangular aluminum. Round vertical legs are not as strong as a square or rectangular leg. As a result, with structurally welded frames and the heaviest gauge tubing, you have the most durable frames possible. We urge you to compare ShoreMaster lifts with any other brand.

What material is used for the pulley?

No matter what size boatlift you purchase pulley material is a critical maintenance issue for any boatlift. Most manufacturers use plastic pulleys because they are cheaper to make. On the other hand, they get brittle over time. The sides of the groove tend to crack and break off allowing the cable to fall out of the pulley. If the cable is already weakened due to rust or broken strands, the cable may break.

Plastic Pulleys

However, if the cable does not break, two things can happen:

- The cable may jam between the pulley and the tube side. As a result, it will become very difficult to raise or even lower the boat. or

- The cable may drag across the pulley shaft. This will put an excessive drag on the cable and eventually wear a groove in the shaft until it breaks the shaft off.

Brass Pulleys

ShoreMaster uses brass pulleys with stainless steel bushings for unsurpassed strength. They simply NEVER wear out or break. Even the smaller jet ski lifts use brass pulleys to minimize maintenance issues.

What is the most popular boatlift used on the Door County Peninsula?

Vertical Boat Lift

The VERTICAL boat lift is the most popular boat lift in Door Couty. It far surpasses the cantilever boatlifts used in the past.

Vertical boatlifts require less water – 6″ vs 12″. They also raise your boat higher. Normal cantilever boatlifts raise your boat 36″ – 40″ high versus a vertical lift which goes to 66″ high. Vertical lifts have capacities up to 7,000 lb.

What is the warranty of the boatlift frame?

Some boatlifts come with a 1 or 2-year factory structural warranty. Some have a five year, and a few have a 10-year warranty. ShoreMaster boatlifts carry a full 15-year structural warranty.

Don’t you deserve the best protection and strength of a ShoreMaster Boatlift?

In Part 4 of this series, the discussion will be the actual calculations to select the correct size boatlift.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Please share a link to this article with them.

PWS is located at 7325 St. Hwy 42/57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection

Our staff is here year-round to assist you.

Feb 12, 2019

WHAT STYLES OF BOAT LIFTS ARE AVAILABLE?

What boat lifts are available for your use? Part 1 of this series discussed the least common types of boat lifts used in Wisconsin waters. Now let’s look at more common types of boat lifts available for your selection.

Hydraulic Boat Lifts

Hydraulic Lift by ShoreMaster

Hydraulic boat lifts generally lift the highest of the available lifts. (up to 6’ high on some models). The lifting height along with the wide stance of the base gives you excellent protection for your boat. It is recommended for high waves and water surges during storms.

Hydraulic boat lifts are D.C. operated units which are quiet and use solar-powered batteries and remote controls.

ELEVATOR LIFTS

12,000# Davit Master Elevator Lift

Elevator Lifts are used with permanent pier installations (usually concrete piers or piling piers.) The elevator lifts raise the boat sideways as shown to the right and below. They lift the boat above the pier height. They are common in channels and lakes with large fluctuations in water depth and no ice movement in winter.

12,000# DavitMaster Elevator Lift

12,000# DavitMaster Elevator Lift

Davit Master Elevator Boat Lifts feature:

- All welded design for strength and durability;

- 6061-T6 Marine Grade Aluminum or Hot-dipped galvanized steel construction;

- Heavy duty adjustable PVC pipe guides with insert reinforcement;

- Adjustable chock system;

- Stainless steel motors for added protection;

- Stainless steel cables with aluminum grooved cable winders

- Aluminum sheaves plus Stainless steel bolts with grease fittings; and

- A Comprehensive warranty.

Some models even allow pivot construction for winter storage.

Floating Rhino Lifts

HANDCRAFTED FOR TOUGH WATERFRONT ENVIRONMENTS

Rhino Lifts were originally built to withstand the brutal marine environment of Lake of the Ozarks, Missouri where very deep water is common. This type of lift is now the preferred choice for boat owners who want the ultimate in strength, durability, and boat lift performance.

Each lift – expertly welded, and hot-dip galvanized also has the highest level of convenience and safety for the people who use it.

The Rhino Lift Floating Boat Lift allows you to raise and lower your lift with the push of a button. You have the peace-of-mind gained from trusting the same equipment used by marinas, restaurants, and resorts across the United States and Canada.

The L-Arm Floating Boat Lift mounts between a U-shaped dock.

Rhino Lift L-Arm Floating Lift

Rhino Lift Front Mount Floating Lift

Front Mount Rhino Boat Lifts require a dock at the front of the lift only. It has a walking platform on three sides for loading and unloading. The lift is only secured at the front of the lift.

These floating lifts cannot be exposed to high waves. As a result, they generally go into marinas or deep water environments.

After reading Part 1 and 2 of this series, you have a better idea about the types of boat lifts generally used in Wisconsin. In Part 3 we will talk about the most popular boat lift used in Door County.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Why not share a link to this article with them?

PWS is located at 7325 State Hwy 57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection. Our staff is here year-round to assist you.

Feb 5, 2019

WHAT SIZE BOAT LIFT DO I NEED?

A boatlift can come in several styles. In this first of a four-part series, we discuss Cantilever, PWC, ShorePorts, and Track systems.

Each boatlift has a specific way it operates, and the conditions under which it should be used. We’ve narrowed the selections down to (8) different types of boat lifts and PWC lifts used most often in N.E. Wisconsin. The more you know about them the more confident your purchasing decision will be.

Cantilever Boatlift

A cantilever lift is generally suitable if you are on a moderate depth inland lake. If the water depth does not fluctuate more than 12” in a boating season, a cantilever lift may work for you.

Cantilever Boatlift by ShoreMaster

Cantilever boatlifts require more water depth than a Vertical lift – (usually 12” of water versus 6″). The lifting rack does not lower into the water as far as other options. Plus, you still have to allow enough water above the lift rack to float your boat on it.

Additionally, they generally have a lifting height of 30” to 40” which is too low for the bay of Green Bay. What if you have waves of 36” or higher or a water surge. Your boat is in danger of getting washed off the rack.

Due to these limitations, a cantilever boat lift is not used on the Door County Peninsula very often. These limitations also mean the resale value is going to be less.

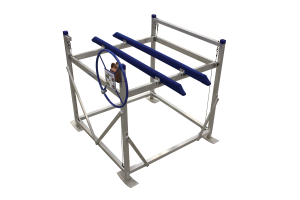

PWC Lift

Vertical PWC Lift by ShoreMaster

PWC (Jet Ski lifts) come in 2 styles: Vertical and Floating. (We have excluded the Cantilever lifts.)

ShoreMaster’s vertical PWC lifts allow you to get into shallow water and raises your boat 50″ high. It operates in the same fashion as a standard vertical boat lift. It provides excellent protection for your PWC.

ShoreMaster PWC Lift

ShorePort

ShorePort PWC Lift by ShoreMaster

ShoreMaster’s Floating lifts (ShorePort) are excellent on rivers that fluctuate in depth, or marinas and inland lakes. They are very simple to use and need very little water to operate. The floating lift requires no maintenance, and you simply drive up onto it. No need to have a motor or crank a wheel.

Wave action above 15” is not recommended for this type of “boatlift.” Combine a floating PolyDock with the PWC floating lift, for the perfect combination on a lake or river.

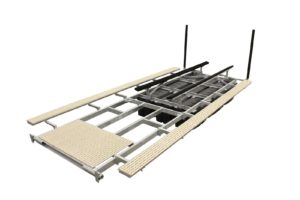

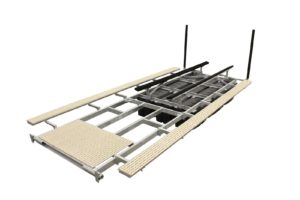

Track or Ramp System

Roll-n-Go Boat Ramp

Roll-n-Go PWC Track System

The track or ramp system is still another option. The personal watercraft ramp comes with a 25-foot nylon loop and winch which prevents scratching while loading the PWC. The basic unit measures 11′ long. There are optional 8′ and 30″ extensions to increase the length of your ramp. How about an adjustable 11″ – 14″ width which accommodates even the largest jet skis.

Basic ramps are available with capacities of 750 lb up to 2,000 lb capacity. See Also: http://roll-n-go.com/

The Track system works best when the supports can be anchored into the ground. Without anchoring, the tracks can move by wave action and the result is a twisted frame. These are ideal for inland lakes when only the basic length is needed, as shown above, and the track is secured.

The PWC or boat can be hand operated or a Lift Boss motor option is available.

Lift Boss

In part 2 of this series we discuss three more options: Hydraulic boatlifts, Elevator lifts, and Floating lifts.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Please share a link to this article with them.

PWS is located at 7325 State Hwy 57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection. Our staff is here year-round to assist you.