May 14, 2020

USED BOAT LIFT GUIDE – Part 2

Are you thinking about buying a used boat lift? This two-part series concludes with four additional items to check. Upon completion, we will have guided you through eight problems to look for when buying a used boat lift.

See Part 1 for the first four checks.

Here’s the second list of things to check:

- Does the cable wind smoothly and correctly on the winch?

- Do the cables have rust on them? Does it use galvanized or stainless steel cables?

- Are there any “kinks” or other visible problems on the cable?

- How often were they lubricated, and with what lubricant?

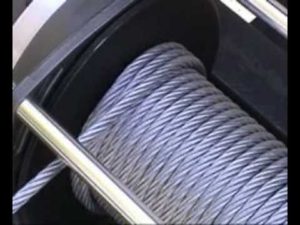

Does the cable wind smoothly around the winch?

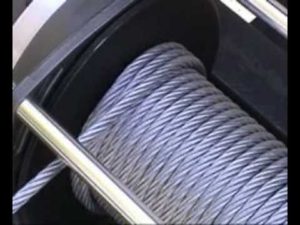

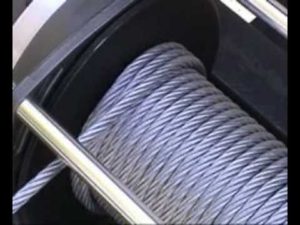

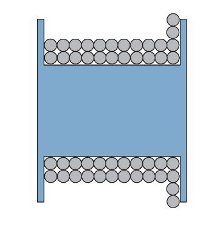

Properly wound Boat lift cable

If you look up inside the winch housing, if it has an enclosure, you will be able to see how the cables are winding. It should be a smooth pattern without any “crossed” cables. If the winch has no outer covering, you can readily see the pattern.

The wire cable has a “memory” to it. Once the cable gets crossed, it will tend to do it again the next time the cable rewinds.

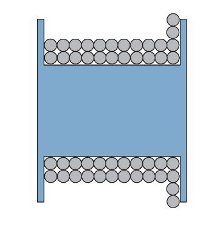

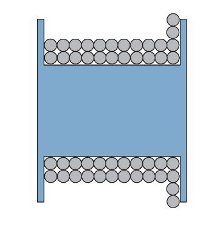

Typical Cable Stacking

If the cable is wrapping in layers, you will get a thunderous sound when the cable finally “falls off” the stack. This movement scrapes the galvanizing of the wire, and rust will form. The “shock” of dropping a 2,000# (or more) weight will also apply excessive stress on the cables.

Do the cables have rust on them?

Galvanized cables will rust over time. The movement of individual strands of the wire against each other cause rust. This movement occurs as they wrap around the winch and pulleys. There is no way to end this.

The only thing you can do is lubricate the cables. The lubrication reduces the friction between individual strands. Lubrication, in turn, lengthens the life of the cable. For more details click HERE.

Rust on the cable indicates that some galvanizing has worn off. Individual wire strands are compromised.

What about rust on a stainless steel cable?

Stainless steel does not rust, but it does pick up loose rust from the winch. Winches are plain steel with a painted surface. When the paint rubs off, the steel will rust and “bleed” onto the cable.

It’s much like a scratch on a car. The rust will run down the side of the vehicle.

The rust typically appears near the winch when the rack is in a lowered position. Under these circumstances, it’s ok. Try to lubricate the cables every year to slow this down.

Are there any visible signs of problems with the cables?

We recommend you lower the “rack” down, but DO NOT allow “slack” to form in the cables. Slack in the cables will allow the windings at the winch to unwind and cross over each other.

It’s much like a fishing reel getting snagged when there is no tension on the line.

Are the cables on the used boat lift adjusted equally?

If three of the four corner cables appear “tight,” the cables will need re-adjustment to re-distribute the weight equally.

Even proper positioning of the boat is essential.

If it takes excessive weight to lower the rack, look at the pulleys in each corner. Are they free to move? Is there sand, seaweed, or reeds packed around the pulleys? Remove any debris to free up the rack.

If any pulleys resist rotation, the rack will not lower smoothly. You must find out why the rack is not moving.

Note: In the case of jet ski lifts, the weight of the rack may not be enough to cause the rack to lower by itself. Have someone lean of the back of the lift to assist the rack in lowering. Still, hanging up? Check all the pulleys as above.

Check the fittings on the ends of the cable. Has rust formed on the fittings, or are there broken strands?

Caution– watch out for the ends of the cables. It’s a painful reminder of exposed strands.

Examine the entire length of the cable for frays (broken strands).

Caution – DO NOT run your hand up and down the cable without leather gloves. Broken strands on the cable will cause painful cuts on an unprotected hand. Ordinary cloth gloves will not protect your hand.

Are there any “kinks” or other visible problems?

Here are the warning signs of defects in your cables.

Frayed Boat Lift Cable

Broken cable strands

Cable damage

wire rope damage

If your cable looks like any of these, it’s time to replace them.

Warning – it is possible to have broken strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

Read this article to learn how to lubricate cables. Lubrication slows down premature corrosion. It’s simple and easy to do.

What is the proper lift cable maintenance?

Cable replacement requires a visual inspection of the lift cables. It’s best to inspect it while it is on dry land to check the critical points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Examine the vertical length of the cable for frayed wires, especially near the winch. Excessive fraying or corrosion near the winch is a top signal of damage.

CAUTION – Always wear leather gloves when sliding your hands along the cable. A frayed wire can cause painful damage to unprotected hands.

There are two types of cable wear:

- Internal cable abrasion- Occurs whenever strands work against each other under load.

- External abrasion – Occurs when the cable bends around the winch drum or against the side of the drum.

Every time the boat is raised or lowered, there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When the strands break, they lose strength.

Assuming the cable is well cared for, how long should it last?

Experts say that to be safe- replace a galvanized cable every two years. All things being equal, the stainless cable will last longer. Up to 2X as long.

A point often overlooked – internal abrasion and rust are hidden, and there may be no visible damage. A boat lift cable like this will fail without prior warning.

When in doubt, plan on replacing the cables. Trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

PWS handles Shoremaster cables and can provide new cables for all brands.

Nothing lasts forever – even boat lift cables.

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

John @ (920) 493-4405 or John@wisconsinpws.com – Scheduling & Service work

Feb 29, 2020

Good Evening, Jerry

Tell your client they are welcome to stop anytime to check out the dock and lift.

Feel free to give them my contact information and I’d be pleased to tell them about my experience working with you. Everyone bent over backward to take great care of me.

All the best.

Casey C. Door County Peninsula, WI

Aug 27, 2019

HOW TO ACCESS A DOCK EASIER

Access to a dock is important to anyone wanting to use a boat. Boating is something both young and old enjoy. Many memories have been created on a boat or a dock. However, those moments are not as easy for some people to enjoy.

What about those who are not physically able to get to the dock or access the boat? It may be someone with an injury to a leg. It may be an older adult. People may have a fear of falling on the shore or getting into a boat.

For some people, access to a boat is an exhausting experience. Still, they want to enjoy the experience and want to be with their family.

What can you do to help them access your boat?

How about starting at the shore end with a longer dock ramp? Why? With the increasingly high waters the last few years you probably find that the standard ramp is now very steep. Your dock has to be installed higher to adjust to these high waters, But you probably have standard 8, 10 or 12-foot ramps. Up until now, these ramps have worked very well. Those ramps, combined with the increased dock heights, have resulted in a steeper angle to walk up. It may be almost impossible for the elderly to access your dock without assistance.

What if a 10′ ramp is still too steep?

Pier & Waterfront Solutions has the solution for you! After all, it’s part of our name!

What if your guests could safely walk over the rocks & the hot sand in comfort?

The first question is – Would you like a longer ramp to reduce the angle? Next, do you have an aluminum dock or a galvanized dock?

Residential gangways may be the answer for you. Residential gangways are available in 16, 20, and 24-foot lengths. The angle would be much lower and it will put your gangway much further up the shoreline to protect your dock in storms.

In most cases, we can even match your existing decking on the residential gangways.

Gangways provide easy access to a dock

What about Commercial aluminum gangways?

Need a longer length? Commercial gangways are available in lengths up to 60′ long. Included handrails give you for even more safety. Remember, commercial gangways come with aluminum decking only. Give PWS a call to get things rolling for Spring 2020.

What about galvanized docks?

PWS recently designed a 20′ galvanized dock ramp that will be available in the spring of 2020. The 20′ galvanized ramp will make your access to the dock much easier.

No more walking over the hot sand or worse yet, the uncertainties of stepping onto the rocks. Is this the year someone will twist their ankle? A twisted ankle (or broken leg or arm) can ruin the summer for months. Crutches get old very fast!

No matter how high your dock is, you will have a gentle walk to the dock height with a gangway. Forget about picking up the sand from the beach and depositing it on the dock. You’ll be walking over it.

What other solutions does PWS offer for your dock and boat lift?

Handrails for dock access safety

Dock Handrails

Dock handrails can be added to your existing dock. Put them on one or both sides of your dock for extra security for the elderly and children. They come in various lengths and mount on all of the Shoremaster Infinity dock systems.

Don’t have a ShoreMaster dock? We can custom make them fit the dimensions you need. We’re all about Solutions!

Boat Loading Handrails

Boat Loading Handrails

Boat loading handrails make it easy and safer to access your boat.from a dock. They give stability for the entire family. Have an elderly parent or friend who could use the extra support and confidence to access the boat? These handrails are a great way to provide a safe experience for them.

Where is PWS?

PWS is located in the center of Door County at 7325 St Hwy 57. That’s 1 mile North of County MM (Hwy 42) and about 5 miles south of Sturgeon Bay. Look for the intersection of Idlewild Road.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Aug 13, 2019

NOTHING LASTS FOREVER – EVEN A LIFT CABLE

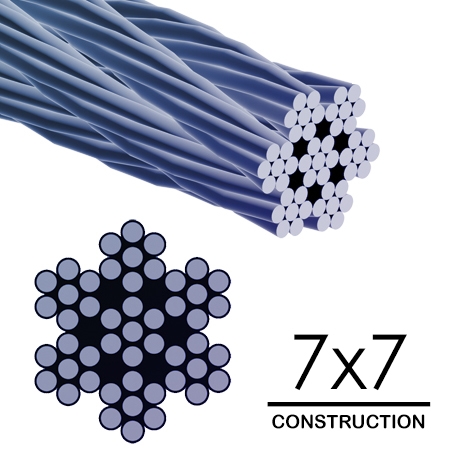

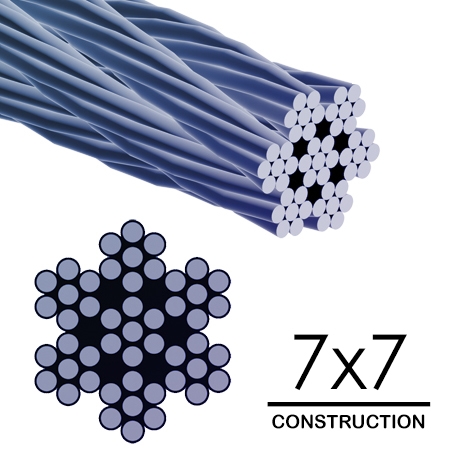

Typical Lift cable

That’s true! Your cables will eventually need replacement. When? That depends on you. If you’ve been around boat lifts for any length of time you have seen problems with boat lifts. Typical problems include corrosion, chafe, broken strands or kinks on the cables..

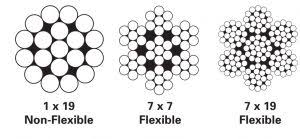

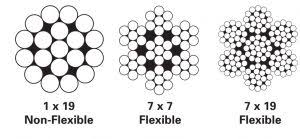

Let’s start by looking at the typical construction of a lift cable.

7 x 7 cable construction

The most common types are the 7 x 7 and 7 x 19 construction. As you can see they are not simply a wire hanging down that lifts your boat up. They are more complex than that.

The individual strands are wrapped together as shown Then they are wrapped again around a core.

HOW DO CABLES GET DAMAGED?

There are two types of wear:

External abrasion

Typical Cable Stacking

This occurs when the cable bends around the winch drum and lift pulleys. On the winch drum, they rub against the adjoining wire or the drum sides. This rubbing causes wear on the external strands which will eventually wear through the individual stands.

If the cable doesn’t wrap properly, it starts to stack on the side of the winch drum. When the cable eventually slips off the “stack”, even though it is only dropping 1/4″ to 1/2″, the resulting noise shocks anyone nearby. It was under hundreds of pounds of pressure from the boat. This situation is usually caused by misalignment of the winch drum or a poorly threaded situation.

New ShoreMaster winches are attached with a complete housing around the upright post which prevents this from happening due to winch misalignment. More on this later in this discussion.

Internal abrasion

Internal abrasion occurs whenever strands work against each other under load. Each time a boat is raised or lowered over a winch drum, there is internal wear. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the strands is the result. When you lose too many strands, you lose a lot of strength. This condition cannot be eliminated but it can be controlled by using the proper size winch drum and pulleys.

A point often overlooked – internal abrasion and the resulting corrosion or rust in a galvanized cable, can be hidden and may not show visible damage. A cable like this may sometimes fail without prior warning.

ASSUMING IT IS WELL CARED FOR, HOW LONG SHOULD IT LAST?

Experts say that to be safe, replace a galvanized cable every two years. All things being equal, stainless wires will last longer-up to twice as long. But don’t rush out and try to change all your cables to stainless. Galvanized cable has its place on your lift. For one, they are stronger than stainless steel and can bend easier around the pulley and winch drum.

An improperly positioned boat may send your boat into the water. See https://wisconsinpws.com/boat-lift-safety-updated/ for more information.

When in doubt, replace the cable. Trying to squeeze another year out of the cable isn’t worth the risk of dropping your boat or personal injury.

COMMON PROBLEMS WITH BOAT LIFT CABLES

Frayed Boat Lift Cable

Chafe or fraying – are those fine broken strands that poke or cut your hands when you slide your hands along the cable. If you catch your clothes when they brush against a cable you have “chafe” or fraying.

Chafe may be the result of faulty sheave alignment or improper drum winding.

Lowering a lift rack without any weight on it, especially on a small lift like a PWC lift, may also result in a “backlash.” This is discussed later.

Note: Be aware that most winches require at least 50 lbs of weight to work correctly.

BROKEN STRANDS

Broken Strands

Broken strands are very dangerous. Boat lifts with this type of damage should be replaced immediately.

CORROSION

Corroded & Frayed Boat lift Cable

Corrosion presents a significant problem for galvanized cables. When the protective layer of galvanizing wears through as discussed above, corrosion will begin. Corrosion may not always be visible to the naked eye. The first time you become aware of the corrosion could be when the cable breaks.

Corrosion may also occur “inside” the cable with little or no external evidence of the damage as discussed above. Any cable showing external signs of rust or corrosion needs replacement.

BACKLASH

Boat lift cable backlash

When a lift is lowered to the bottom and the winch continues to move the result will be a Backlash. If there is insufficient tension on the cables they will “spring” in every direction on the winch drum. When you retighten the cable, the loose cables become snarled and can wrap up like a backlash in a fishing reel.

WHAT IF I EXPERIENCE A BACKLASH?

Whenever a cable experiences a backlash DO NOT use your bare hands to repair the problem (chafe). You won’t soon forget this if it happens to you. People have also lost fingers when a cable snaps back onto a winch drum. Make sure you wear leather gloves and keep tension on the cable at all times. Keep your hand at least 12″ from the winch to prevent entanglement.

When you experience a backlash, lower the boat into the water to prevent the cables from interleaving further on the drum.

Never use bare fingers or pliers to align the cables. As always, carefully handle it to avoid breakage of the wire strands.

Next, unwind the winch while keeping tension on it. Do this until you see the bottom layer on the drum. Re-wrap the cable onto the winch drum while maintaining tension. Rewind it in even layers. Be sure to close any gaps between the cable on the winch drum.

Finally, it is time to return your boat to the lift to raise it, making sure the cable continues to wind smoothly. If the problem persists, call your lift dealer (that’s PWS)

DID YOU REMEMBER THE WIRE “MEMORY”?

Properly wound cable

“Memory” allows the cable to play out and rewind onto the drum in a neat pattern. The wire must wind in a set pattern. Loose that “memory” and misalignment occurs which will cause the cable to turn against the side of the winch drum.

Maintain tension at all times to prevent the cable from interleafing with the windings in a lower layer. Fill in each layer completely, leaving no gaps.

WHAT’S COMING UP NEXT WEEK?

Next week we give you more information about boat lift cables and what you can do to lengthen their life.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts, and accessories.

We are located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection with Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Jun 18, 2019

WALKING PLATFORM FOR JET SKI LIFTS

Walking Platform

A walking platform for your ShoreMaster vertical jet ski lift is an essential add-on from Pier & Waterfront Solutions. These stainless steel walking platforms are made exclusively for the SM 1064 and SM 1264 jet ski lifts (PWC lifts).

The walking platform consists of a stainless steel, perforated platform that mounts securely to the lift rack. The platform never rots and is extremely strong. It’s simple to install – one 9/16″ wrench is all you need. No drilled holes required

A stainless steel walking platform provides a stable platform for loading, refueling, or working on your jet ski.

Duel walking platforms

The platform allows easy access to both sides of the jet ski. With access on both sides, the platform will enable you to put a cover on while high and dry.

Why scramble over your jet ski to put a cover around it? Why get tossed around by the waves while trying to work. There won’t be any more standing on the lift rack where the risk of falling off or injury is the greatest.

Imagine being able to service and refuel your jet ski without having to stand in the water or pulling it up on the rocks. Now you have a loading platform to set your equipment on when working on the engine or re-fueling your unit. You can do all kinds of work and stay dry.

Want more?

ShoreMaster winch tube extension

How about a winch extension post which allows you to reach the winch wheel from your dock? The aluminum extension post comes in a kit and will enable you to move the winch up, so you have better access to the winch wheel. A dock set high out of the water will no longer be a problem. No need to lay on the pier to reach the wheel?

Where can you find Pier & Waterfront Solutions?

We are located in the center of the Door County Peninsula at 7325 St. Hwy 42/57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Don’t forget – Give us a call If you have a dock or boatlift topic you would like to see addressed on our site.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.