Feb 5, 2019

WHAT SIZE BOAT LIFT DO I NEED?

A boatlift can come in several styles. In this first of a four-part series, we discuss Cantilever, PWC, ShorePorts, and Track systems.

Each boatlift has a specific way it operates, and the conditions under which it should be used. We’ve narrowed the selections down to (8) different types of boat lifts and PWC lifts used most often in N.E. Wisconsin. The more you know about them the more confident your purchasing decision will be.

Cantilever Boatlift

A cantilever lift is generally suitable if you are on a moderate depth inland lake. If the water depth does not fluctuate more than 12” in a boating season, a cantilever lift may work for you.

Cantilever Boatlift by ShoreMaster

Cantilever boatlifts require more water depth than a Vertical lift – (usually 12” of water versus 6″). The lifting rack does not lower into the water as far as other options. Plus, you still have to allow enough water above the lift rack to float your boat on it.

Additionally, they generally have a lifting height of 30” to 40” which is too low for the bay of Green Bay. What if you have waves of 36” or higher or a water surge. Your boat is in danger of getting washed off the rack.

Due to these limitations, a cantilever boat lift is not used on the Door County Peninsula very often. These limitations also mean the resale value is going to be less.

PWC Lift

Vertical PWC Lift by ShoreMaster

PWC (Jet Ski lifts) come in 2 styles: Vertical and Floating. (We have excluded the Cantilever lifts.)

ShoreMaster’s vertical PWC lifts allow you to get into shallow water and raises your boat 50″ high. It operates in the same fashion as a standard vertical boat lift. It provides excellent protection for your PWC.

ShoreMaster PWC Lift

ShorePort

ShorePort PWC Lift by ShoreMaster

ShoreMaster’s Floating lifts (ShorePort) are excellent on rivers that fluctuate in depth, or marinas and inland lakes. They are very simple to use and need very little water to operate. The floating lift requires no maintenance, and you simply drive up onto it. No need to have a motor or crank a wheel.

Wave action above 15” is not recommended for this type of “boatlift.” Combine a floating PolyDock with the PWC floating lift, for the perfect combination on a lake or river.

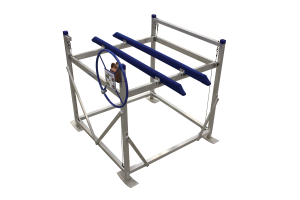

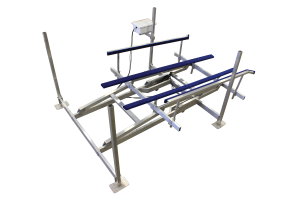

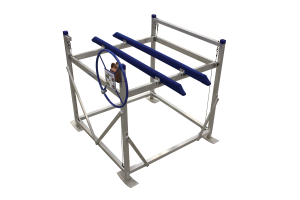

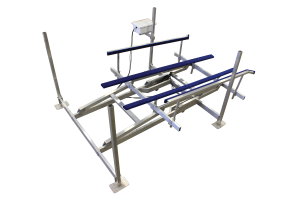

Track or Ramp System

Roll-n-Go Boat Ramp

Roll-n-Go PWC Track System

The track or ramp system is still another option. The personal watercraft ramp comes with a 25-foot nylon loop and winch which prevents scratching while loading the PWC. The basic unit measures 11′ long. There are optional 8′ and 30″ extensions to increase the length of your ramp. How about an adjustable 11″ – 14″ width which accommodates even the largest jet skis.

Basic ramps are available with capacities of 750 lb up to 2,000 lb capacity. See Also: http://roll-n-go.com/

The Track system works best when the supports can be anchored into the ground. Without anchoring, the tracks can move by wave action and the result is a twisted frame. These are ideal for inland lakes when only the basic length is needed, as shown above, and the track is secured.

The PWC or boat can be hand operated or a Lift Boss motor option is available.

Lift Boss

In part 2 of this series we discuss three more options: Hydraulic boatlifts, Elevator lifts, and Floating lifts.

Publication Dates

Part 1 of 4 – Cantilever, PWC, ShorePorts, Tracks Feb 5, 2019

2 of 4 – Hydraulic, Elevator Lifts, Floating lifts Feb 12, 2019

3 of 4 – Vertical lifts Feb 19, 2019

4 of 4 – Calculations Feb 26. 2019

Do you have a friend that may be interested in this information? Please share a link to this article with them.

PWS is located at 7325 State Hwy 57, that’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay at the Idlewild Road intersection. Our staff is here year-round to assist you.

Jul 17, 2018

Nothing lasts forever – including boat lift cables

Boat Lift cable problems require a thorough explanation.

There are two types of normal cable wear:

- Internal cable abrasion- This occurs whenever strands work against each other under load.

- External abrasion – This will occur when the cable bends around the winch drum and rubs against the adjoining cable wrap. It also occurs when the cable rubs against the side of the winch drum

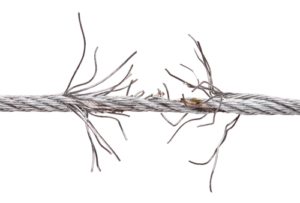

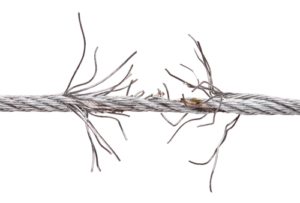

Frayed Boat Lift Cable

Types of Steel used as a Boat Lift Cable

Galvanized Steel: Galvanized steel is carbon steel made corrosion resistant by the application of a thin layer of zinc oxide. A “hot dip” in a molten zinc bath results in galvanizing the cable. The process applies a thin layer or coating of zinc to the steel to increase the metal’s resistance to corrosion.

Galvanized steel is less expensive than stainless steel due to the differences in the processing of each. Galvanized steel is stronger than stainless steel. The downside to galvanized steel is the fact that it has a higher electron-potential than stainless steel, making its’ corrosion resistance less effective because it does NOT regenerate when damaged.

Stainless Steel: Stainless steel is carbon steel which is mixed with about 10% chromium to resist oxidation or corrosion. The chromium forms a chromium oxide layer that promotes resistance to corrosion. When exposed to oxygen the protective coating WILL regenerate. The anti-corrosion of the chromium merely needs oxygen to maintain this property of resistance.

All Lift Cables Will Require some Maintenance

The winch and lift cables require periodic attention. Remember, these (2) items do all the “work” on your lift. They do the lifting of the rack assembly with the weight of the entire boat and motor on it.

Boat lift cables are manufactured out of either stainless or galvanized steel.

Galvanized cable is used as the winch cable on heavy boats. Stainless steel cables are used for the remaining cables on top brands like ShoreMaster.

Both types of steel offer the benefit of corrosion resistance and strength. However, watch for the noteworthy differences mentioned above that require your attention.

Corrosion

Galvanized cables that break usually show signs of corrosion or rust in advance. Typically, the failure is located near the winch when the rack is in a lowered position. Another common site for corrosion is at the bottom of the cable where it secures to the frame on some brands.

Rusted Boat Lift Cable

A slight discoloration indicates that the protective galvanizing coating may have worn away. Heavy concentrations of rust indicate that the steel cable is losing strength and requires replacement immediately.

How long should a cable last?

Experts claim galvanized cables require replacement every two years. All things being equal, a stainless cable will last up to twice as long.

A point often overlooked – internal abrasion or rust is hidden and may not show external damage on the cable during a visual inspection. A boat lift cable like this may sometimes fail without prior warning.

Other causes of cable failure

An improperly positioned boat puts extra strain on any boat lift cable. Wave action pounding against the boat hull or jamming the rack against the frame may send your boat into the water with a corroded or damaged cable. Even a new cable may “snap” if you jam the rack against the frame.

When in doubt, replace the cable; trying to squeeze another year out of a $95 cable that you know s damaged or rusting isn’t worth the risk.

In Conclusion… What Can You Do For Your Boat Lift Cable?

- In spring and fall put a short blast or two of PENETRATING OIL on the cables. Spray the cables wrapped around the winch drum from the top of the winch. Do not soak the cable; you’ll only contaminate the water. Use only penetrating oil. A quick spray during the summer is very helpful.

- NEVER USE GREASE to lubricate the cables. (grease traps the moisture inside the cable accelerating its deterioration).

- Inspect cables for frays and rust – Caution – wear leather gloves to prevent injury to your hands. Check near the top of the winch cable as this is the most common area for frays. Replace as needed.

- Check all cables to assure correct alignment on the rack pulleys.

- With your boat correctly positioned on the lift, check for any slack in the cables. All cables should be equal in tension. Contact PWS for adjustment, if needed.

- Look for cable corrosion near the winch with the rack all the way down. Maintain weight on the rack to assure proper tension on the cables.

We hope that this article will make your life easier and lend more confidence to your selections. Your boat lift is an investment, and as such we want to help you make wise decisions.

Reminder

PWS is located in the center of Door County at 7325 St Hwy 57. It is located 1 mile North of County MM (Hwy 42) and South of Sturgeon Bay. Look for the intersection of Idlewild Road.

Want us to address a dock or boat lift topic for you? Feel free to give us a call.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.

Jun 5, 2018

How to Select BoatLifts – Part 2

Boatlifts come in several configurations. In part 1 of this 2 part series, we discussed vertical and cantilever lifts. What about boatlifts for larger boats?

Next, we’ll discuss Elevator and Hydraulic boatlifts.

Elevator Lift

The elevator boatlift can only be mounted on permanent piers. These piers usually consist of a concrete pier (or concrete capped, boulder pier) or as an alternate a pier mounted on permanent pilings. As shown below, the elevator lift raises the boat parallel to the pier for easy access to the boat. They are commonly used in channels and lakes with significant fluctuations in water depth.

Elevator BoatLifts

The elevator lift is powered by one or two synchronized A.C. electric motors depending on the unit size. There is no need to hand-crank this lift. A wireless remote control is used to raise or lower the boat.

Elevator boatlifts are capable of stopping anywhere along its vertical travel so it makes it simple to load and unload a boat. This boatlift makes the boat readily accessible for covering with a boat cover and loading.

Hydraulic BoatLift

In general, Hydraulic boatlifts will travel 4’, 5′ or 6’ vertically depending on the model ordered. They will handle loads up to 32,000 lbs.

Because the base is wider than a typical cantilever or vertical boat lift, you have more stability in storms.

The Hydraulic lift is one of the best for high waves and water surges. The D.C. operated units are quiet and use solar-powered batteries and wireless remote controls. No A.C. power required.

Hydraulic BoatLifts by ShoreMaster

Where can you find the solution to any boatlift situation?

At Pier & Waterfront Solutions, of course!

PWS is located 1 mile North of County MM (Hwy 42) at 7325 St. Hwy 42/57. That’s just 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Our staff is ready to assist year round.

Call if you want to see an issue discussed on our site.

Contact Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com with your questions.

May 29, 2018

What is the right Boat lift for Me? – Part 1

Purchasing a new boat lift is a very confusing time You have a lot to consider before making your decision. This article will help you make your lift selection easier.

Where will you be using the boat lift?

One factor in your lift selection process is its suitability for the body of water you will be using it on. Will you be on a large bay or lake where waves can be strong? Will it be a river or small lake with minimal wave action?

In NE Wisconsin, Green Bay and Lake Winnebago present unique problems for boaters. These two bodies of water have significant fluctuations in water depth and wave action. Wave action of 3 or more feet added to increasing water depth during a surge will cause significant problems for boaters.

When these two factors combine, you will want a lift that raises high enough to keep your investment from being damaged.

Consider Frame Construction

You need durable frame construction to withstand the boat weight and pressures from the moving water.

ShoreMaster Vertical Boat Lift with welded side frames

Are the side frames all welded construction? Are the side frames simply bolted together? Most brands use bolts everywhere, so shipping is less expensive. This results in frame movement over time. Movement results in elongated holes and a weaker frame structure.

What are the Boat Lift Frame Materials?

The most popular boat lifts in N.E. Wisconsin has aluminum frames and stainless steel cables.

What is the Warranty of the frame material?

Boat lifts come with a 1 or 2-year factory structural warranty. Some have a five year, and a few even have a 10-year warranty.

ShoreMaster boat lifts carry a full 15-year structural warranty. This 15-year warranty is the result of the all-welded side frames. Bolts are only used to assemble the side frames to the cross members.

Most brands use bolts everywhere, so shipping is less expensive, but this results in frame movement over time. Movement results in elongated holes and a weaker frame structure.

Your boat deserves the extra protection and strength of a ShoreMaster boat lift.

What type of cable do they use?

Boat lifts today have either galvanized, stainless steel or a combination of both. Stainless steel cables last as much as 2 – 4X longer than galvanized cable. Stainless steel cable is not as strong as galvanized but the manufacturers increase the cable and winch diameters to compensate.

There are limits to the diameter of the cabling used. The winch drum diameter limits the cable diameter. A thick cable wrapping around a small drum flexes the cable unnaturally resulting in premature cable failure.

Boat length, width, and weight?

Consider not only the length, width, and weight of the boat you have now but also the possibility of a larger boat in the future. This may not be the deciding factor in your boat lift decision, but don’t ignore it altogether. It can be the difference between:

- Buying a new boat OR

- Buying a new boat AND a new boat lift.

Manual or Electric operation

Do you want to raise your boat by using the hand wheel or use a motor to do all the work for you? Nature powers most lift motors through a D.C. motor and battery setup.

ShoreMaster Boat Lift with a DC Motor

A.C. versions, while available, require 120 V power at the boat site and need more care to prevent electrical shock.

Resale values

While cantilever boat lifts generally cost less than vertical lifts initially, consider the resale value if you decide to get a larger boat which requires a new lift. Cantilever lifts typically have less resale value because they can be used in fewer applications. Vertical lifts allow you to function in shallower water and raise your boat higher. For this reason, they hold their value more than a cantilever boat lift.

See Part 2 for additional information

Where can you find the solution to any boatlift situation?

At Pier & Waterfront Solutions, of course!

PWS is located at 7325 St. Hwy 42/57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Our staff is ready to assist year round.

Call If you want to see an issue discussed on our site.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com with any questions.

Mar 13, 2018

Boatlift Cable Maintenance (Revisited)

Boatlift cables, properly maintained, will keep your boatlift functioning the way it is meant to operate. Perform a visual inspection of all cables, especially on the winch, on a regular basis.

The most frequent cause of issues with a boatlift involves a problem with the cables resulting from:

- Misalignment;

- Chafing (fraying);

- Corrosion (rust);

- Overloading;

- Improper Drum Winding; or

- Boatlift cables without tension

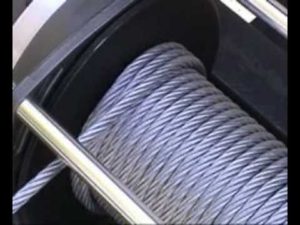

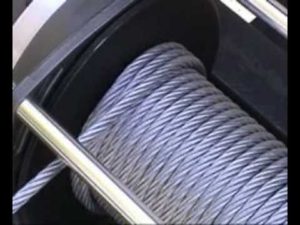

Properly wound boatlift cable

Properly wound Boatlift cable

Cables must wind tightly and neatly on the winch drum as shown here.

Boatlift Cable improperly wound on the drum

Without tension on a cable, the cable unravels on the drum. The unraveling of the cable is like a “backlash” on a fishing reel. Re-winding the cable results in the cable winding against the side of the pulley drum. A loose winding of the cables allows an excess gap between the cable windings on the drum.

Boatlift Cable Backlash

Boatlift cable backlash

When loose cables are re-tightened on the winch drum, they become flat, snagged or tangled. The result is uneven wear and damaged strands.

What if I experience a backlash?

Caution: Whenever a cable becomes jammed, there may have been an overrun (backlash) on the drum. DO NOT use your hands to repair the problem. People have lost fingers when a cable snaps back onto a winch drum.

Caution: If you are attempting to re-align the cables on the drum make sure to wear leather gloves and keep tension on the cable at all times. Keep your hand at least 12” from the winch. Broken cable strands cause painful cuts and punctures in your hands.

When you experience a backlash, lower the boat into the water to prevent the cables from interleaving on the drum.

Never use bare fingers to align the cables. As always, carefully handle the cable to avoid breakage of the wire strands.

Never use pliers to hold tension on the cable as this will damage individual strands on the cable.

Next, unwind the cable while keeping tension on it, until you see the bottom layer on the drum. Re-wrap the cable, under pressure, in even layers. Be sure to close any gaps between the cables on the winch drum.

Finally, it is time to return your boat to the lift to raise it making sure the cable continues to wind smoothly.

If the problem persists, call your lift dealer.

Don’t forget about cable “memory.

“Memory” allows the cable to plays out and rewind onto the drum in a neat pattern. The cable must wind in a set pattern. Loose that “memory” and misalignment occurs which will cause the cable to wind against the side of the winch drum.

This misaligned cable will drop off the “stack” and cause a loud, violent sound as it drops back onto the lower winding.

The cable must remain under tension at all times to prevent the cable from interleafing with the windings in a lower layer.

What is Boatlift Cable Chafe?

Frayed Boat Lift Cable

“Chafe” are those fine broken strands that cut your hands or catch your clothes when you slide your hands along the cable.

Chafe often results from faulty sheave alignment or improper drum winding. Lower a boatlift rack without any weight on it and the result will be a “backlash.” The backlash could result in additional damage to the cables.

Note: A lightweight jet ski rack may not go down as you unwind the cable with no weight on the lift rack. Be aware of this situation and try to keep constant tension on the cable at all times.

Boatlift Cable Corrosion

Corrosion presents a significant problem for galvanized cables. When the protective layer of galvanizing wears through, corrosion will begin. Corrosion may not always be visible to the naked eye. The first time you become aware of the corrosion may be when the cable breaks.

Corroded & Frayed Boatlift Cable

Corrosion may also occur inside the cable with little or no external evidence of damage.

Any cable showing external signs of rust or corrosion needs replacement.

Overloading and Boat Positioning

Make sure your boat is positioned correctly on the lift. If it’s not far enough forward, it will put excessive weight on the rear cables and the frame structure. The boat is also prone to washing off the lift in a storm from wave action.

Too far forward may damage the lower motor assembly or break the front cables due to excess weight.

In general, a boat has most of its weight at the stern. As a result, the stern should be about 12″ – 18″ from the lift rack. This position distributes the weight evenly across the lift rack and prevents overloading the cable system.

What Cable Maintenance am I able to perform myself?

A visual inspection of the cables needs to occur on a regular basis. It is helpful to do this when the lift rack is in its lowest position. In this situation, most of the cable is available for inspection. Look for chafing, corrosion or flat cable especially near the winch box.

Don’t forget – do this inspection with leather gloves on to protect your hands. At the beginning of the boating season, be sure to apply a short burst of penetrating oil to the top of the cables wrapped on the winch drum. The penetrating oil will work its way down the cable as needed.

Boatlift Cable Lubricant

Boat Lift Cable Lubricant

Do not be afraid to do it more often during the summer months, if you use the boatlift a lot.

Never apply grease to the cables. Grease prevents the moisture from escaping the cable and winch drum. Most quality lifts use Stainless Steel cables for a majority of cables and (1) galvanized cable as the winch cable. Trapping moisture in the cables causes them to corrode faster.

To summarize, take care of your cables, and they will last for years.

Where can you find Pier & Waterfront Solutions?

We are located in the center of the Door County Peninsula at 7325 St. Hwy 42/57. That’s 1 mile North of County MM (Hwy 42) and 3 miles South of Sturgeon Bay. Look for the Idlewild Road intersection.

Our staff is always ready to serve your needs.

Don’t forget – Give us a call If you have a dock or boatlift topic you would like to see addressed on our site,

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.