Jun 29, 2021

How Long Will a Boat Lift Last?

Your boat is a BIG investment. You want to protect it for years to come. It only makes sense that your boat lift system should last at least as long as your boat. If your boat lift is well-built and maintained, it can last 25 years or more. In general, a boat lift will last much longer if you take care of it.

Look at these areas as part of a regular boat lift maintenance schedule.

Weight Warnings

A properly sized boat lift will handle the weight of your boat plus the equipment you put in it. PWS will assist in selecting the proper size and type of boat lift for your hull and shoreline conditions.

The average boat up to 20′ will weigh in the 4 – 6,000 lb range. This includes the fuel, water, gas, motor(s). Don’t forget your passengers – including your friend – Big Bubba.

Don’t let people get in or out of the boat while it’s on the lift to avoid straining the system. When you’re not using your boat, remove the drain plug at the back of the boat. Rainwater can’t collect and add extra weight (roughly 8 lbs/gallon) if you do. Don’t forget to replace it before you go out again.

Lift Cables and Pulleys

Lubricate your cables with penetrating oil instead of grease. Replace any cables with rust spots, broken strands, fraying, or kinks. Grease the lift pulleys if required. Be sure to check the nuts and bolts to ensure tightness.

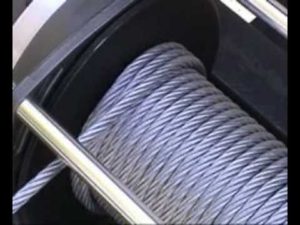

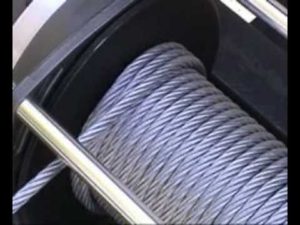

Boatlift cable backlash

Check your winch drum as the cable is winding onto it to avoid slack, misalignment, and uneven wear. Never allow your lift cables to go slack. A slack line will result in damage to the system. It’s like a backlash on a fishing pole, only with a rigid steel cable. It can be challenging to unravel.

Never use a screwdriver or hit the cable with a hammer in an attempt to release the line. You’re almost guaranteed to cause severe damage.

Motors, Gearboxes, and Drive Units

If your boat lift has a motor, examine it for signs of rust or water retention. Ensure that any holes on the top of the motor or winch are closed.

The bottom holes must be open for proper drainage.

Inspect your gearbox and drive units regularly. Check for appropriate alignment, damaged cables, and areas that need lubrication.

Lift beams

Inspect your bunk carpeting for wear and tear and any wood underneath the carpet for cracks and rot. Lift beams should be kept out of the water when not in use. Better yet, get an aluminum/vinyl set and never have to replace the carpeting again.

Keep your hardware tightened, and be sure that the bunks line up correctly with your boat hull.

Storage

If you’re storing your lift in the off-season, remove the battery if you have a power hoist. Store it on a small piece of wood. Store your lift with the cradle or platform to the top.

Your boat lift protects your boat, so it’s essential to keep it in good condition.

Proper care and maintenance can help you avoid costly damage. Your dock and accessories need to be inspected for damage, also. Check your manufacturer’s guidelines for more specific care instructions.

Weight

It’s up to you to stay within the manufacturer’s specifications. Staying within those specs is crucial.

Even lifting a boat with the wrong hull design can cause damage. Never add more weight to your boat while it’s on the lift.

Entering or exiting a boat while it’s on a boatlift can be very dangerous. Ensure you have proper weight distribution when lifting.

Lubrication

Cables are usually made of stainless steel and need lubrication. Regularly apply penetrating oil or chain and cable fluid to reduce abrasion.

Make sure not to use grease on the cables. Grease traps moisture inside the cable strands. However, boat lift motor components and pulleys usually require grease.

Since you’re lubricating your lift, check for damaged cables that need to be repaired, replaced, or tightened.

Water-Related Damage

Boat docks and lifts are still susceptible to water-related damage. Lift beams and bunks can be damaged by a boat coming in “hot.” When docking, check your speed, so you are not going faster than you are willing to hit the dock.

Keep your lift out of the water as much as possible. Small amounts of rust can be ground off and touched up.

Never place a plastic bag or cover over the winch and/or motors in the winter. Condensation will form inside and cause excessive damage.

Alignment

Uneven wear can shorten cable lifespan, so keep an eye on the cable alignment. Make sheave alignment part of your regular inspections. Keep an eye on the winder, drum, and spool.

If you notice a backlashed cable, slack, or other boat lift problems- STOP. Don’t go any further. Adjust the cables immediately. If you’re not sure of the alignment, contact the professionals at PWS.

Reminder – Use leather gloves to protect your hands when handling the cables.

Storage

Even off-season storage can contribute to how long your boat lift lasts. Store your boat lift with the platform up.

If you have a power hoist, remove the battery and store it inside on a small piece of wood.

Signs of Lift Damage

Once the flood or storm has died down, clear any debris off of your dock and lift. Look for bent or twisted beams, damaged drives, or broken bunks on your lift. Look for bent or damaged bolts and loose fasteners.

Check the lift cables for kinks, abrasions, frays, or breaks. Do not operate your lift until those cables are repaired or replaced.

If your boat lift shifted during the storm, realign it and make it square with the dock. When there are high waves, make sure the boat is still in the correct position.

Consult your installation manual or PWS for more information about adjustments. Even if everything looks good, make sure that you perform a test run of your lift. Check for any problems before you get back to boating.

At times large objects, like logs or other debris, strike your boatlift during the night or when you are away. Always look for damage if there was a storm.

ShoreMaster boat lifts are made with premium components. They make the best equipment to protect your boat.

In summary

Invest in the best boat lift brand to protect your boat – ShoreMaster.

Where can you find Pier & Waterfront Solutions?

Pier & Waterfront Solutions, 7325 St. Hwy 57, is located 3 miles south of Sturgeon Bay. Go 1 mile PAST the intersection with County MM (heading north). Look on the right at the intersection of Idlewild Road and Hwy 57.

PWS is

Pier & Waterfront Solutions remains “open” year-round.

The Covid-19 virus is waning thanks to the population getting vaccinations. We hope that the remaining people will get the vaccine to help stop the spread of this deadly virus. We will continue to conduct as much business as possible by email, text, or phone to do our part to keep people safe.

Site visits continue as usual. When making in-person contacts, we follow “social distancing” guidelines when possible by doing any face-to-face contact outdoors.

PWS display yard – OPEN 24-7

Red Tag

PWS‘s display area is always open for you to examine at your leisure. All displays available for sale have a numbered, red tag on them. Want more information on something you saw in our yard? Please reference that number when you inquire.

PWS provides estimates by email to make the process faster, safer, and paperless.

Call, message, or email Jerry with any questions.

Jerry Englebert

Contact Jerry at 920-493-4404 for more information or use this link.

Apr 13, 2021

What is the BEST hydraulic boat lift for Green Bay & Lake Michigan?

Want the BEST hydraulic boat lift for Green Bay waters? Look no further than the latest addition to Pier & Waterfront Solutions premier lines. PWS now features Sunstream SunLift™ hydraulic lifts.

Pier & Waterfront Solutions recently diversified the selection of hydraulic lifts. You now have a choice of hydraulic lifts with capacities up to 30,000 lbs. and lifting heights to 6′-6″.

What does this mean for you?

Want the fastest, free-standing hydraulic lift with the greatest lifting height and smoothest operation? Check out Sunstream SunLift.™

Sunstream SunLift Hydraulic boat lift

Here’s a side-by-side comparison of the three most popular brands:

HYDRAULIC BOAT LIFTS

Sunstream ShoreMaster Shorestation

Capacity – 2,000 – 30,000# 4,000–12,500# 2,000–15,000 #

Lifting Height – 36″- 78″ 36″– 60″ 70″

Min. Depth* – 12″ 12″ 14″-21″

Wireless Remote – Y Y Y

Inside Width – > Boat width 108” – 132” 108” – 144”

Cables Used? NO NO YES

*Plus the draft of the boat

Ease of operation

Today you can use your boat as easily as you use your car. Get out on the water more often, and have more fun.

Sunstream has wireless remote controls and optional motor-stop and guide-on systems. These features make operating and docking easy even for a new skipper. There are NO Cables Used.

Sunstream pioneered the hydraulic, free-standing boat lift revolution. They continue to advance the technology and is known for reliability, durability, and safe design.

Sunstream SunLift™ has been proven with years of service in salt and freshwater environments. Sunstream has a wide range of accessories to optimizes the lift for your specific needs.

We’ll have more details in the coming weeks.

Where is Pier & Waterfront Solutions?

Pier & Waterfront Solutions, 7325 St. Hwy 57, is located 3 miles south of Sturgeon Bay. Go 1 mile PAST the intersection with County road MM (heading north). Look on the right at the next corner – Idlewild Road and Hwy 57.

Is PWS OPEN?

Pier & Waterfront Solutions remains “open” year-round.

Please use face masks

The Covid virus continues to spread and affects many people. Don’t be one of them.

PWS is conducting as much business as possible by email, text, or phone.

Site visits continue as usual. When making in-person contacts, we follow “social distancing” guidelines when possible.

PWS display yard – OPEN 24-7

PWS‘s display area is always open for you to examine at your leisure. All displays available for sale have a numbered, red tag on them. Want more information on something you saw in our yard? Please reference that number when you inquire.

Red Tag

PWS will provide estimates by email to make the process faster, safer, and paperless.

Call, message, or email us today with any questions.

Call Jerry at 920-493-4404 for more information or use this link.

Jun 16, 2020

A Boat Lift Safety Lesson

My lift cable broke…and I can’t ….

Proper boat lift safety means you won’t have to learn the tough lesson pictured here. If you apply these recommendations, you can relax and enjoy your boating experience.

Failure to follow these safety suggestions may result in damage to your boat or even personal injury.

Boat Lift Safety = Never exceeding the Ratings

The rated capacity of any lift is the maximum capacity, and you should never exceed that amount.

Boat weight INCLUDES more than just the published weight of the boat. It also includes the weight of fuel, water, and equipment. After all, you will be lifting all of this when you raise your boat. It adds up very quickly!

Plus, we recommend that you allow at least a 300-500# margin of error when you calculate the boat weight. See also: Sizing a Boatlifts: How to select the correct Boat Lift.

If you ever hear a salesperson say, “You can easily go 40% or 50% over that rating without a problem”. You are at risk of being the owner of the boat above if you follow that flawed thinking.

What’s the real story?

Lift cables are rated much higher than the rating of the boat lift. As an example, (using imaginary numbers) your boat lift has a 4,000# rating, it could have cables rated for 6,000# to 8,000#.

The cable rating may be 6,000#, but ONLY if the wires are in perfect shape – meaning no burrs, kinks, frays, or rust. These defects reduce the load capacity of the cables.

The lift racks are correctly rated for the weight regardless of the cable ratings. If someone is trying to sell you a 4,000# lift and telling you that it can handle up to 4,700# – WALK AWAY!!

The load must also be “balanced” on the rack for proper boat lift safety. (More on this later)

Lift cables fail without warning

Sorry!! Cables don’t “creak” or “groan” as a warning of impending danger. The only sound you hear is a loud “snap” followed by the sound of your boat hitting the water.

In a storm, you want to get your boat as high above the water as possible. Yet, raising a boat until the lifting platform or rack hits the frame is NOT the way to do it.

Hitting the frame is an all too common occurrence. Ask yourself, if raising the boat that extra ½” is worth snapping a cable. You risk damage to your boat and lift, or worse yet, personal injury.

Operate Lift Motors properly or break a cable

Properly used, an electric lift motor is a real back saver! I wouldn’t be without one. But you need to exercise extra care when using a lift motor. Shutting off a lift motor does not mean the lifting action will stop. What if it “drifts”?

For example, one brand of lift motor “drifts” after the motor stops. The “drift” potentially causes the lift rack and frame to jam together.

Cable failure, lift or boat damage, personal injury, or worse may be the result.

When the rack hits the lift frame, something has to give. The most likely culprit will be the cables. If you combine a damaged cable with a rack hitting the frame, you have a recipe for disaster.

OK, You Jammed the Rack & Frame! – What comes next?

You were distracted, and now the rack is jammed against the frame. A jammed rack means your next step is critical.

You’re in a hurry to release the pressure, but be sure you know which way the motor will go when you flip the switch.

If the rack isn’t going “DOWN,” damage occurs almost instantly. If it is a broken cable – your boat goes down – even faster!! Starting the winch or motor in the wrong direction could mean your boat will be in the water in an instant. Did I mention it won’t be floating?

Proper Positioning of the boat is part of boat lift safety.

As if a jammed rack wasn’t enough, did you know there are right ways and wrong ways to position your boat on your lift?

Boat stern overhanging too far

All lift ratings are based on a “balanced load.” In other words, the weight of the boat must be relatively equal on each end of the rack.

When you put the majority of the weight on one end of the rack, cable breakage is more likely.

The heaviest part of any boat will be where the engine is mounted. That could be at the stern (outboards) or even near the middle of the boat (inboards).

A boat placed too far forward on the lift rack results in excessive weight on the “front” of the lift. Too far to the stern of the boat puts too much weight on the rear cables. If the cables have weakened by corrosion or fraying, you risk impending disaster.

What is the correct position for a boat on a lift?

You can determine the proper positioning of a boat by placing the stern of the boat within 12″ – 18″ of the rear lift rack. Now, raise the rack slightly out of the water.

Next, try to lift the bow end with your hands. If the boat weighs 3,500# and you can lift the front of the boat, you are either “Mr. Atlas” or the boat is positioned to the rear. If you can lift the bow at all, your boat is too far back. The weight is not evenly distributed across the four corners of the lift. Lower the boat and reposition it forward.

The boat shown here overhangs about 36″ from the rack and risking major damage. By placing the boat too far back on the rack, a majority of the weight is on the rear cables. What if those cables are weak from corrosion or fraying?

Does high water affect the positioning of a boat?

Yes, it does. In the example above, with the rear of the rack overloaded, the boat has only minimal weight on the front rack.

Your boat will float on a wave. When the bottom of the boat is “lapped” by a wave, it will try to raise the boat. With repeated lifting (or bouncing) the boat can work it’s way off the rack. It will try to go go to the rear. Eventually, the boat will literally “bounce” right off the lift.

With a balanced boat, you have a better chance of the boat staying on the rack.

Align the boat in the same position each time.

So, now you have repositioned your boat until you found a good position for a balanced load. What comes next?

It’s time to make a note of a fixed object on the boat and how it lines up with something on the lift. This is a good gauge for the next time you enter your lift. Always try to go back to this same position.

Summary

You now know the do’s and don’t of boat lift ratings and positioning for your boat. With this knowledge, you can Relax and Enjoy your boating experience.

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

That’s not all!

4. Some employees are working remotely, but they are always available by phone.

5. Any employee exhibiting symptoms or illness is sent home.

6. We provide estimates and invoices by email to make the process paperless and faster.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can YOU do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

So, YES – WE ARE OPEN!

Please call, message, or email us with any questions.

Thank you for allowing us to work with you.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Scheduling & Service work

May 26, 2020

10 Best Boat Docking tips

Docking a boat or putting it into a boat lift is not the favorite activity for any boater. Until you feel confident about what you are doing, it can be down-right terrifying. It was so easy to go out. – why can’t it be just as simple to come back in?

Follow the best boat docking tips shown here and it will make it easier for any boater.

- Always put safety first. Check the surrounding area before approaching a dock. Kids love to swim under the dock to greet you.

- VERY IMPORTANT – How fast are you going? Are the waves pushing you too fast? Are you willing to hit the dock or boat lift at that speed?

- Remember – Slow speeds will always give you more time to correct your course. Slower speeds also cause less damage. On the flip side, it is harder to control the boat at slower speeds.

Follow the next steps for greater control:

- Always turn the wheel BEFORE applying any power – not during or after. This is very important for a single-engine boat.

Note – Twin inboards? Keep your hands off the wheel with twin inboards. If you do turn the wheel, the boat may take an unexpected path when you try to use the engines.

- Apply short bursts instead of steady power to the engine. You won’t build up a lot of momentum, and you will have better control of the boat. Speed and momentum are the opposite of control.

- Always stay under power. Without power, you can not control the direction of the boat. Keep the engine on so you can maneuver as necessary.

- Secure all ropes and make sure they are not wrapped around anyone’s hands or feet.

- Always communicate with passengers as you approach the dock. Managing your crew or guests before and during docking is important to make docking safer.

- Always reduce your windage in heavy winds. Particularly in a small boat.

- Don’t worry about stopping and doing it over again. If you see a problem, it’s better to reverse the motor than hit something. On your next pass, it may be better – come back for another try.

Tell Your Friends & Family

Have friends or neighbors you believe should see this article? Email them this link – and Thank you!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north at the next intersection (Idlewild Road and Hwy 57).

We look forward to talking to you.

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Scheduling & Service work

May 14, 2020

USED BOAT LIFT GUIDE – Part 2

Are you thinking about buying a used boat lift? This two-part series concludes with four additional items to check. Upon completion, we will have guided you through eight problems to look for when buying a used boat lift.

See Part 1 for the first four checks.

Here’s the second list of things to check:

- Does the cable wind smoothly and correctly on the winch?

- Do the cables have rust on them? Does it use galvanized or stainless steel cables?

- Are there any “kinks” or other visible problems on the cable?

- How often were they lubricated, and with what lubricant?

Does the cable wind smoothly around the winch?

Properly wound Boat lift cable

If you look up inside the winch housing, if it has an enclosure, you will be able to see how the cables are winding. It should be a smooth pattern without any “crossed” cables. If the winch has no outer covering, you can readily see the pattern.

The wire cable has a “memory” to it. Once the cable gets crossed, it will tend to do it again the next time the cable rewinds.

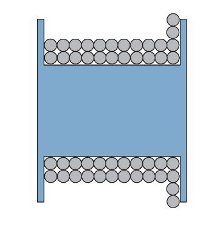

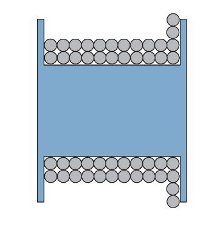

Typical Cable Stacking

If the cable is wrapping in layers, you will get a thunderous sound when the cable finally “falls off” the stack. This movement scrapes the galvanizing of the wire, and rust will form. The “shock” of dropping a 2,000# (or more) weight will also apply excessive stress on the cables.

Do the cables have rust on them?

Galvanized cables will rust over time. The movement of individual strands of the wire against each other cause rust. This movement occurs as they wrap around the winch and pulleys. There is no way to end this.

The only thing you can do is lubricate the cables. The lubrication reduces the friction between individual strands. Lubrication, in turn, lengthens the life of the cable. For more details click HERE.

Rust on the cable indicates that some galvanizing has worn off. Individual wire strands are compromised.

What about rust on a stainless steel cable?

Stainless steel does not rust, but it does pick up loose rust from the winch. Winches are plain steel with a painted surface. When the paint rubs off, the steel will rust and “bleed” onto the cable.

It’s much like a scratch on a car. The rust will run down the side of the vehicle.

The rust typically appears near the winch when the rack is in a lowered position. Under these circumstances, it’s ok. Try to lubricate the cables every year to slow this down.

Are there any visible signs of problems with the cables?

We recommend you lower the “rack” down, but DO NOT allow “slack” to form in the cables. Slack in the cables will allow the windings at the winch to unwind and cross over each other.

It’s much like a fishing reel getting snagged when there is no tension on the line.

Are the cables on the used boat lift adjusted equally?

If three of the four corner cables appear “tight,” the cables will need re-adjustment to re-distribute the weight equally.

Even proper positioning of the boat is essential.

If it takes excessive weight to lower the rack, look at the pulleys in each corner. Are they free to move? Is there sand, seaweed, or reeds packed around the pulleys? Remove any debris to free up the rack.

If any pulleys resist rotation, the rack will not lower smoothly. You must find out why the rack is not moving.

Note: In the case of jet ski lifts, the weight of the rack may not be enough to cause the rack to lower by itself. Have someone lean of the back of the lift to assist the rack in lowering. Still, hanging up? Check all the pulleys as above.

Check the fittings on the ends of the cable. Has rust formed on the fittings, or are there broken strands?

Caution– watch out for the ends of the cables. It’s a painful reminder of exposed strands.

Examine the entire length of the cable for frays (broken strands).

Caution – DO NOT run your hand up and down the cable without leather gloves. Broken strands on the cable will cause painful cuts on an unprotected hand. Ordinary cloth gloves will not protect your hand.

Are there any “kinks” or other visible problems?

Here are the warning signs of defects in your cables.

Frayed Boat Lift Cable

Broken cable strands

Cable damage

wire rope damage

If your cable looks like any of these, it’s time to replace them.

Warning – it is possible to have broken strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

Read this article to learn how to lubricate cables. Lubrication slows down premature corrosion. It’s simple and easy to do.

What is the proper lift cable maintenance?

Cable replacement requires a visual inspection of the lift cables. It’s best to inspect it while it is on dry land to check the critical points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Examine the vertical length of the cable for frayed wires, especially near the winch. Excessive fraying or corrosion near the winch is a top signal of damage.

CAUTION – Always wear leather gloves when sliding your hands along the cable. A frayed wire can cause painful damage to unprotected hands.

There are two types of cable wear:

- Internal cable abrasion- Occurs whenever strands work against each other under load.

- External abrasion – Occurs when the cable bends around the winch drum or against the side of the drum.

Every time the boat is raised or lowered, there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When the strands break, they lose strength.

Assuming the cable is well cared for, how long should it last?

Experts say that to be safe- replace a galvanized cable every two years. All things being equal, the stainless cable will last longer. Up to 2X as long.

A point often overlooked – internal abrasion and rust are hidden, and there may be no visible damage. A boat lift cable like this will fail without prior warning.

When in doubt, plan on replacing the cables. Trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

PWS handles Shoremaster cables and can provide new cables for all brands.

Nothing lasts forever – even boat lift cables.

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

John @ (920) 493-4405 or John@wisconsinpws.com – Scheduling & Service work