Jun 9, 2020

32 STEP CHECKLIST FOR A BOAT

This 32 step checklist for your boat will start your boating season off right.

Do you have spring fever? Are you itching to get your boat or jet skis back in the water? It’s been a L-O-N-G winter. Now it’s time to de-winterize your boat before taking it out for its first trip of the season.

Following a spring checklist, like the one below, can help prevent a host of problems. Skipping them could keep you out of the water later in the season.

We all know how fast storms come up on Green Bay. Don’t get caught unprepared. Make sure the boating season goes smoothly and safely.

HERE’S A SPRING CHECKLIST FOR A BOAT:

- Is your boat registered?

- Be sure to empty the old fuel and add fresh fuel.

- Are the fuel shut-off valves on the tank and at the engine working?

- Is your blower switch (if any)working?

- Recharge your battery and fill with distilled water, if needed.

- Secure the batteries in ventilated containers that are non-corrosive and liquid-tight.

- Fit non-conductive covers over the posts.

- Is the lower-case leak-free?

- Check the electrical system, including fuses, spark plugs, and wires.

- Inspect the propeller for damage.

- Is there any damage to the hull (blisters and cracks)?

- Flush the water tank.

- Replace any oil filters and lubricate all parts.

- Are all lines checked?

- Check the hydraulic steering system for leaks and fluid levels.

- Inspect the steering and throttle cables.

- Are all fire extinguishers charged?

- Is everyone familiar with how to operate them? Make sure that at least one can be reached from the helm or cockpit.

- Are life vests checked for wear, abrasions, weak or torn seams, secure straps, and buckles?

- Inspect the bilge pump, if any, for cleanliness and absence of obstructions. Check this frequently throughout the season.

- Check the engine compartment for excess water.

- Are the lights on your boat operational?

- Check the electrical cables and connections for loose, disconnected, or corroded conductors.

- Have you taken a boating safety course?

NOW YOU’RE READY TO GO.

- If you are towing your trailer to its launch point, you will also need to inspect it before your first outing. In particular, are the lights working properly?

- Be sure to tell someone responsible where you’re going.

READY TO LAUNCH

- Is the drain plug in place? You’d be amazed how often this happens.

- Follow all safe launching practices.

- Watch for kids in your path.

- Ventilate the bilge for several minutes before starting the engine.

- Watch the engine temperature and cooling system.

- Make sure everyone follows safe boating practices.

Now you’ve done the work – It’s time to enjoy the benefits!

Tell Your Friends & Family

Have friends or neighbors you believe should see this article? Email them this link – and Thank you!

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

- Conducting as much business as possible by email, text, or phone.

- Site visits will continue but with limited in-person meetings.

- When in-person contacts are necessary, we will follow “social distancing” guidelines.

- Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

- Some employees will be working remotely, but they are always available by phone.

- Any employee with symptoms or illness is sent home.

- We continue to provide estimates and invoices by email to make the process paperless.

- Crew starting times are being staggered to limit social interactions.

- We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can YOU do to help us?

- Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

- When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – WE ARE OPEN!

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Scheduling & Service work

May 28, 2020

Is Your Pier Missing a Dock Storage Box?

Is a Dock Storage Box on your summer shopping list? How many times do you walk to your pier, only to kick yourself because you wish you had a storage box? Do you always forget something? Every time you set foot on your dock, do you think of all the equipment you could store in it? Where do you store the life preservers? Wouldn’t a dock storage box be convenient?

What Makes A Great Storage Box?

Unsure of what to look for in a storage or dock box? Are you afraid to purchase one because you don’t know enough about them? Read on to find helpful info about storage boxes. They will make life much easier for you.

Does the Storage Box Have Tight Fits?

Water Laser Cutting Technology, used on the best dock storage boxes, ensures the best fit. This process offers a consistent, precision cut for all the various pieces. This precision makes for a superior fit. Precision cuts and quality hinges fit together better. The box is less likely to suffer from leaks or damage.

Additionally, these dock storage boxes constructed from fiberglass provide a far superior product.

What’s The Alternative?

The alternative, polyethylene (plastic) storage boxes, fade, discolor, and warp in sunlight. As a result, this depreciates its usage and aesthetic value.

Fiberglass dock storage boxes also come with a gel-coat finish to add an extra layer of protection. Like polyethylene dock boxes, the gel-coat finish will oxidize in sunlight. So what’s the difference then? The difference is, you can buff and wax the oxidation off of the box to keep it looking brand new, year after year.

Buffing and waxing increase the durability of the box in the form of scrape and cut resistance. You can buff and wax any imperfections with a rubbing compound and watch them disappear. The process is like cleaning the hull of a boat on a smaller scale.

Do Polyethlene Dock Storage Boxes Have Gel-Coating?

Polyethylene dock storage boxes do not have a gel-coat finish. Once the sun damages the plastic material, it’s impossible to restore the surface to a like-new finish again.

The failure of the polyethylene storage boxes to withstand the sun will cause you to consider buying a new dock box. This type of failure will happen much sooner with a Polyethylene box than if you had chosen a fiberglass dock box initially.

Choose quality first to save time and money.

Assorted Dock storage Box sizes

Dock storage boxes come in many sizes including:

98″ x 22″ x 24.5″ H 85″ x 22″ x 24.5″

72″ x 26.5″ x 27.5″ 74″ x 38″ x 36″

71″ x 22″ x 24.5″ 33″ x 24″ x 18″

44.5″ x 26.5″ x 27.5″ 39.5″ x 19.75″ x 21.5″

Triangular and Low profile versions are also avaiable. Call for more information.

Not enough room to mount a dock box on your dock?

PWS has alternatives including, side mounts, for the boxes.

NEW – this year!

This year PWS has another alternative that was not available in the past. Talk to Jerry about trading your dock for the new 3-Season Pier, which we are now offering.

This new steel dock can handle storms better due to it’s higher weight and the “open” decking we use. Combining these two features makes it the heaviest pier on Green Bay. It has survived installations on Lake Michigan also.

An additional feature is the 4′ x 10′ “L,” which is standard on the 3-Season dock. This allows 16 sq feet more than lesser docks. It makes it easier to mount a dock box, enter a boat lift, and entertain your friends.

Tell Your Friends & Family

Have friends or neighbors you believe should see this article? Email them this link – and Thank you!

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Scheduling & Service work

May 14, 2020

USED BOAT LIFT GUIDE – Part 2

Are you thinking about buying a used boat lift? This two-part series concludes with four additional items to check. Upon completion, we will have guided you through eight problems to look for when buying a used boat lift.

See Part 1 for the first four checks.

Here’s the second list of things to check:

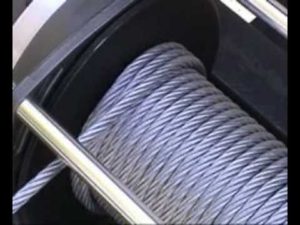

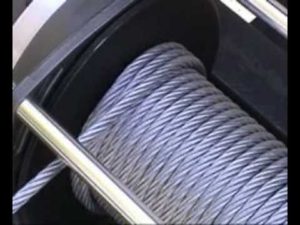

- Does the cable wind smoothly and correctly on the winch?

- Do the cables have rust on them? Does it use galvanized or stainless steel cables?

- Are there any “kinks” or other visible problems on the cable?

- How often were they lubricated, and with what lubricant?

Does the cable wind smoothly around the winch?

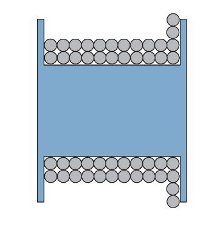

Properly wound Boat lift cable

If you look up inside the winch housing, if it has an enclosure, you will be able to see how the cables are winding. It should be a smooth pattern without any “crossed” cables. If the winch has no outer covering, you can readily see the pattern.

The wire cable has a “memory” to it. Once the cable gets crossed, it will tend to do it again the next time the cable rewinds.

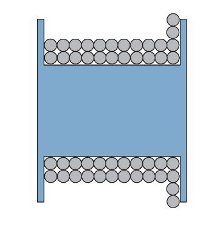

Typical Cable Stacking

If the cable is wrapping in layers, you will get a thunderous sound when the cable finally “falls off” the stack. This movement scrapes the galvanizing of the wire, and rust will form. The “shock” of dropping a 2,000# (or more) weight will also apply excessive stress on the cables.

Do the cables have rust on them?

Galvanized cables will rust over time. The movement of individual strands of the wire against each other cause rust. This movement occurs as they wrap around the winch and pulleys. There is no way to end this.

The only thing you can do is lubricate the cables. The lubrication reduces the friction between individual strands. Lubrication, in turn, lengthens the life of the cable. For more details click HERE.

Rust on the cable indicates that some galvanizing has worn off. Individual wire strands are compromised.

What about rust on a stainless steel cable?

Stainless steel does not rust, but it does pick up loose rust from the winch. Winches are plain steel with a painted surface. When the paint rubs off, the steel will rust and “bleed” onto the cable.

It’s much like a scratch on a car. The rust will run down the side of the vehicle.

The rust typically appears near the winch when the rack is in a lowered position. Under these circumstances, it’s ok. Try to lubricate the cables every year to slow this down.

Are there any visible signs of problems with the cables?

We recommend you lower the “rack” down, but DO NOT allow “slack” to form in the cables. Slack in the cables will allow the windings at the winch to unwind and cross over each other.

It’s much like a fishing reel getting snagged when there is no tension on the line.

Are the cables on the used boat lift adjusted equally?

If three of the four corner cables appear “tight,” the cables will need re-adjustment to re-distribute the weight equally.

Even proper positioning of the boat is essential.

If it takes excessive weight to lower the rack, look at the pulleys in each corner. Are they free to move? Is there sand, seaweed, or reeds packed around the pulleys? Remove any debris to free up the rack.

If any pulleys resist rotation, the rack will not lower smoothly. You must find out why the rack is not moving.

Note: In the case of jet ski lifts, the weight of the rack may not be enough to cause the rack to lower by itself. Have someone lean of the back of the lift to assist the rack in lowering. Still, hanging up? Check all the pulleys as above.

Check the fittings on the ends of the cable. Has rust formed on the fittings, or are there broken strands?

Caution– watch out for the ends of the cables. It’s a painful reminder of exposed strands.

Examine the entire length of the cable for frays (broken strands).

Caution – DO NOT run your hand up and down the cable without leather gloves. Broken strands on the cable will cause painful cuts on an unprotected hand. Ordinary cloth gloves will not protect your hand.

Are there any “kinks” or other visible problems?

Here are the warning signs of defects in your cables.

Frayed Boat Lift Cable

Broken cable strands

Cable damage

wire rope damage

If your cable looks like any of these, it’s time to replace them.

Warning – it is possible to have broken strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust.

Read this article to learn how to lubricate cables. Lubrication slows down premature corrosion. It’s simple and easy to do.

What is the proper lift cable maintenance?

Cable replacement requires a visual inspection of the lift cables. It’s best to inspect it while it is on dry land to check the critical points. Ideally, the lifting platform (or rack) should be in the lowered position. Of course, make sure the lift cable is not allowed to go slack.

Examine the vertical length of the cable for frayed wires, especially near the winch. Excessive fraying or corrosion near the winch is a top signal of damage.

CAUTION – Always wear leather gloves when sliding your hands along the cable. A frayed wire can cause painful damage to unprotected hands.

There are two types of cable wear:

- Internal cable abrasion- Occurs whenever strands work against each other under load.

- External abrasion – Occurs when the cable bends around the winch drum or against the side of the drum.

Every time the boat is raised or lowered, there is internal wear on the cable. Each strand of wire in the winding is moving at a slightly different speed. Abrasion of the cable strands is the result. When the strands break, they lose strength.

Assuming the cable is well cared for, how long should it last?

Experts say that to be safe- replace a galvanized cable every two years. All things being equal, the stainless cable will last longer. Up to 2X as long.

A point often overlooked – internal abrasion and rust are hidden, and there may be no visible damage. A boat lift cable like this will fail without prior warning.

When in doubt, plan on replacing the cables. Trying to squeeze another year out of a $75 cable isn’t worth the risk of dropping your boat or personal injury.

PWS handles Shoremaster cables and can provide new cables for all brands.

Nothing lasts forever – even boat lift cables.

Don’t Forget – Considering rip-rap for your shoreline? PWS is the place to contact!

Where is Pier & Waterfront Solutions?

Located at 7325 St. Hwy 57, it’s 3 miles south of Sturgeon Bay, and 1 mile past the intersection of Cty MM (heading north). Look on the right side, one mile north, at the next intersection (Idlewild Road and Hwy 57).

ARE WE OPEN?

During this time of uncertainty, Pier & Waterfront Solutions is staying “open.” We have implemented measures to ensure the safety of our employees and visitors. At the same time, we are working to maintain the trusted service that you have come to expect.

We are implementing these precautionary measures:

1. Conducting as much business as possible by email, text, or phone.

2. Site visits will continue but with limited in-person meetings. When in-person contacts are necessary, we will follow “social distancing” guidelines.

3. Our display yard is always open for you to examine at your leisure. All displays have a numbered, red tag on them. If you want more information or pricing, please reference that number.

Is there More?

4. Some employees will be working remotely, but they are always available by phone.

5. Any employee with symptoms or illness is sent home.

6. We continue to provide estimates and invoices by email to make the process paperless.

7. Crew starting times are being staggered to limit social interactions.

8. We keep the same crews together to limit cross interactions.

With these measures, we hope everyone will stay safe, and we will be back to normal operations soon.

What can you do to help us?

1. Please conduct as much business as possible via emails, messaging, and emails. This step protects everyone involved.

2. When you see our crews installing equipment, please practice “social distancing.”

Thank you for allowing us to work with you.

So – YES – ARE WE OPEN?

Please call, message, or email us with any questions.

Let’s all stay safe!

Contact:

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – Commercial work & new/used Sales.

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – Erosion control & shoreline work.

John @ (920) 493-4405 or John@wisconsinpws.com – Scheduling & Service work

Mar 17, 2020

Wire Rope Lubricants

Wire rope lubrication is critical to extending the life of a cable (often referred to as the “lift cable”). How significant is it? Failure to complete this simple maintenance can reduce wire rope life by up to 50%.

Tell me more!

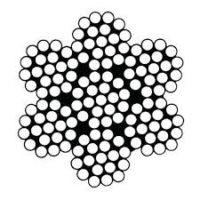

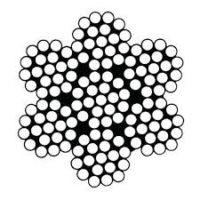

A wire rope consists of wire strands wound around a central core, then again wound around themselves to form a wire rope. The center may consist of steel or even plastics. Here are just some of the MANY different configurations for a wire rope.

Wire Rope Configurations

The use of a small strand size is better suited to bending around small sheaves (pulleys). Taken to an extreme, a wire made of one thick “strand” would not be able to go around a pulley.

Many small strands allow the wire rope to bend easily around the pulleys. In doing so, the strands “rub” against each other, causing friction. Over time, friction rubs any external coatings off the wire rope.

How are the wire rope strands protected against rust?

Uncoated wire rope strands left “uncoated” will rust from exposure to moisture in the air;

The cable strands get a coating of zinc for rust protection (called galvanizing). The steel strands travel through a hot zinc bath to coat the surface with rust protection. The “con” to galvanized cables – the surface does not regenerate when damaged.

What about stainless steel cables?

In simplest terms, when molten high carbon steel mixes with chromium, it forms stainless steel. When in contact with air, the chrome restores the anti-rust properties. The “con” side – it gives up small amounts of strength.

What function does lubricating a wire rope perform?

Wire rope lubricants;

1. Reduce friction in the layers of the wire rope as they move over other layers. It’s true for galvanized & stainless steel cables both; and

2. Lubricants provide corrosion protection and lubrication in the core of the cable. Less rust and friction means longer life for the cables.

Are there different lubricants used?

Boat Lift Cable Lubrication

There are different types of wire rope lubricants – penetrating and coating. Solvents in penetrating oils carry a lubricant into the core of the wire rope. When the solvent evaporates, it leaves behind a lubricating film to protect the strands.

“Coating” lubricants (grease) barely penetrate a cable. The coating seals the outside of the cable from moisture and reduces wear and corrosion. But, it also seals moisture inside the cable, thus promoting the rusting process.

PWS recommends only penetrating lubricants.

Most wire ropes fail on the inside first. It is vital to ensure that the center core receives enough lubrication. Repeated applications over a day are a good idea.

It is best to apply short bursts of spray lubricant on the top cables wound around the drum. Spray across the top of the wires to get the best penetration and protection. The rope strands tend to separate slightly due to bending around the winch drum. This separation allows the lubricant better access to the core of the wire rope.

Four Rules to follow:

- Do not apply a grease lubricant on a boat lift cable;

- Never change the diameter of the lift cable;

- Never substitute a different wire construction; and

- Do not replace stainless steel cables with galvanized cables.

Experience suggests that life cycles may double with lubrication. But remember, there are other factors affecting wire rope life also.

PWS attributes the increase in the life cycle to the use of penetrating oil to displace water and decrease friction. The oil reduces the wear and corrosion occurring inside the rope. Spraying with a penetrating lubricant acts like an oil change for cars. You’d never allow your vehicle to run out of oil. Right?

The savings from lubrication versus replacing a lift cable are considerable.

What else can damage a boat lift cable?

Improper winding and shock loading with heavy loads damage the cables. These actions will speed up wear and corrosion. See this link.

WHAT ABOUT MY BOAT LIFT?

In a previous post, we explained the danger to boat lift cables if the waves hit the bottom of your boat. We also demonstrated what defective wires look.

7 x 7 cable construction

Rust on galvanized cable

Once again, here are the warning signs of defects in your cables.

Broken Strands

If your cable looks like any of these, it’s time to replace them.

Warning – It is possible to break strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust. If you see “rust” on a stainless steel cable, it is from the winch drum depositing rust in the winding process.

Visit Pier & Waterfront Solutions on Facebook also.

Tell Your Friends & Family

Have friends or neighbors you believe would like to see this article? Email them this link – they’ll thank you!

Where is PWS?

You will find us at the intersection of Idlewild Road and Hwy 57 in Door County. The address is 7325 St. Hwy 57, Sturgeon Bay. That’s 3 miles south of Sturgeon Bay, and 1 mile north of the intersection with Cty MM.

Our staff looks forward to serving ALL your waterfront needs.

Contact:

Dave @ (920) 905-2588 or Dave@wisconsinpws.com – erosion control and shoreline work.

Jerry @ (920) 493-4404 or Jerry@wisconsinpws.com – commercial work and new & used Sales.

John @ (920) 493- 4405 or John@wisconsinpws.com – Scheduling & Service work.

Sep 3, 2019

It’s time to think – winter storage.

It seems like just yesterday when the days began getting longer and the temperatures were rising. Now the temperatures are rapidly falling and the days are getting shorter.

Labor Day has come and gone. Traditionally, it signals the end of summer. Many people are shutting down their summer retreats and preparing them for winter storage. They are packing up and heading home. We have people from all over the country – from Florida to California and many places in between.

The Door County peninsula is a favorite retreat for many people, including Bear fans. We’ll see many of you in a few days – Sept 5th (Packers vs. Bears)

In the meantime, we hope that you will remember to call John (920-493-4405) and let him know when you are ready for the removal of your equipment. (i.e., your boat is off your lift).

While you are busy closing up your retreat, our crews are once again removing docks and boat lifts for winter storage. The water cools off quickly, and they have to go into it daily. We want to avoid working in the morning ice this year.

What can you expect this year?

The farther we get into September, the bigger the storms become. When a storm is in the forecast, we can’t respond fast enough to get everyone out of the water. Once a storm hits your equipment, there is nothing we can do except to wait it out. If there is widespread damage along the Door County shoreline it takes time to get to everyone.

Preparing for winter storage

Our equipment can go into about 4 feet of water (the operators’ cab is flooding at that point). Our crews get more than wet feet when that happens.

The sooner you notify us that you are ready, the better the chances we have to get your equipment out of the water.

Due to the potential for big storms, we try to handle the Bay first and then the inland lakes.

What should change this Fall?

We recommend that you allow us to place your equipment further up on your property. Why?

Due to the substantial damage encountered in the Spring of 2019. We understand that it may look unsightly and it’s difficult to cut the lawn under it. Plus, there may appear to be dead spots under the footpads in Spring. However, nature recovers quickly. Isn’t that better than what you see here?

Wrong winter storage

Ice Shove

In some cases, the ice moved more than 50 feet up on to the shore and lawns. In one case right into the house.

Crushing a deck and house

These are just some of the winter conditions we can expect each year. With the high water this year we expect to see even more of this in the Spring of 2020.

Remember

Pier & Waterfront Solutions (PWS) specializes in all ShoreMaster docks, lifts, and accessories.

We are located in the center of Door County at 7325 St Hwy 57, just south of Sturgeon Bay at the intersection with Idlewild Road. Our staff looks forward to serving all of your waterfront needs.

Call Jerry at 920-493-4404 or Email Jerry@wisconsinpws.com for more information.